Factors affecting the efficiency of die cutting punching machine

Several factors affecting the efficiency of die cutting punching machine

The die cutting machine is mainly used for the die cutting, creasing and cold pressing operations of trademarks, cartons, greeting cards, etc. in the paper product packaging and decoration industry. It is an important equipment for post press packaging processing. At present, the die cutting machines in the packaging market are mainly divided into: automatic die cutting machine, manual die cutting punching machine, etc. Among them, the manual die cutting punching machine has a slow production speed and low technical content. At the same time, the equipment has serious hidden dangers in terms of operational safety. Because it needs manual feeding in the production process, it is prone to industrial accidents, and at the same time, it runs like a tiger’s mouth, so people give it a nickname “slot machine”. So, how to improve the safety linkage performance of manual die cutting punching machine and prevent industrial accidents? How to transform the production technology of flat die cutting machine to speed up production efficiency?

Discuss the types and improvement prospects of die cutting machines

Main content: Die cutting machines are mainly divided into three types: round pressing, round pressing and flat pressing according to the different imprinting forms. According to the form of template placement, it can be divided into vertical and horizontal. There are three types of manual die cutting punching machine, semi automatic die cutting machine, and automatic die cutting and creasing machine according to the degree of automation. In terms of function, in addition to die cutting, there is also hot stamping function, called hot stamping die cutting machine, and some with automatic stripping function, called die cutting machine with stripping.

Retrofit hotspots of automatic flatbed die cutting machine

Main content: Fully automatic flatbed die cutting machine is a key equipment for improving labor productivity in the post press processing of printed and packaged products. It is not only an efficient, safe and high quality die cutting machine. The updated products have been favored by the majority of packaging and printing enterprises. The wide application and broad market prospect of this kind of equipment have attracted many equipment manufacturers.

Seven major problems of die cutting machine that should be paid attention to and improved

Main content: Flatbed die cutting machines mostly use equal indexing cam mechanisms, and whether the shape of the cam is reasonable is the key. The tightness of the chain should be moderate, too tight or too loose will affect the die cutting accuracy. The paper feeding gripper bar of the flat die cutting machine is mostly solid, but it is easy to deform during high speed movement, and the inertia is large during emergency stop. A good quality gripper bar has high hardness and light weight, and the angle and pressure are moderate.

Several factors affecting the efficiency of die cutting punching machine

With the development of packaging machinery, food packaging, gift packaging and wine packaging are becoming more and more important. The packaging boxes are of different shapes and have their own characteristics.

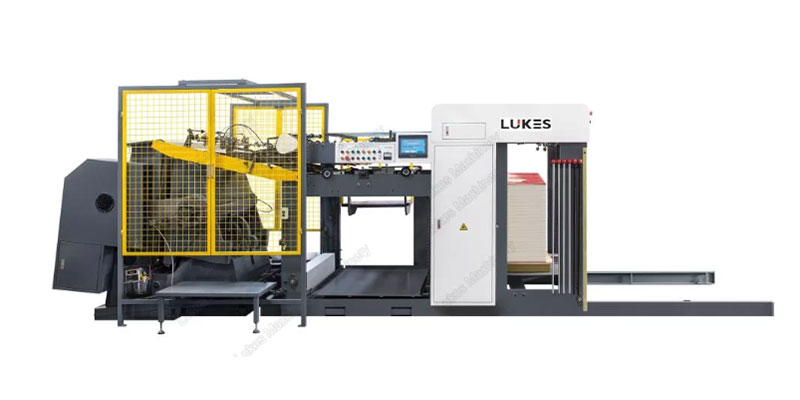

Manual die cutting punching machine is the earliest packaging machinery product used in paper product packaging machinery. From the most primitive mode of fool die cutting machine to the current fully automatic flat bed die cutting machine, the technology is very mature. Among the machines with mature technology, shandong lukes machinery provides you with several points of attention that affect efficiency :

- Die cutting speed: The fully automatic die cutting punching machine has a very fast diecutting speed, which has been several times faster than the old diecutting machine.

- Paper feeding size and height: With the development of the design process, the feeding size and height of the automatic flat diecutting machine have been continuously improved, and more different types of cardboard products can be diecut;

- Paper feeding method: The traditional paper feeding method is to use the conveyor belt to feed the paper, and the new cardboard diecutting machine adopts the automatic paper suction technology. The automatic paper suction technology can achieve the characteristics of fast and accurate paper suction;

- Stability of die cutting punching machine: The current die cutting machine technology is relatively mature, and the die cutting speed and accuracy have been very stable. Therefore, the stability of the flat die cutting machine has been done very well.