Three Customer Acquisition Strategies for the Automatic Die-Cutting Machine Industry in 2025

Cutting a New Blue Ocean! Three Customer Acquisition Strategies for the Automatic Die-Cutting Machine Industry in 2025

The automatic die-cutting machine industry is at the cusp of transformation. Against the backdrop of intelligent manufacturing, restructuring of global trade, and upgrading downstream demand, the traditional model of relying on low-price competition and single-point breakthroughs in equipment performance is no longer able to sustainably attract effective customers. Companies need to restructure their customer acquisition strategies from the three dimensions of technology, market, and marketing to accurately target high-value customers in this trillion-yuan market.

I. Using technological upgrades to directly address the pain points of high-growth industries

Circular die-cutting and laser die-cutting technologies are becoming key for equipment manufacturers to break into traditional markets. Circular die-cutting machines, with their continuous die-cutting process, offer significant advantages in long-run production, supporting high-speed, high-precision, multi-process, and high-volume production requirements. Laser die-cutting technology, on the other hand, uses direct computer-controlled laser cutting, eliminating the need for die cutting, making it particularly suitable for cutting complex patterns and small batches. The global high-power laser die-cutting machine market is expanding at a compound annual growth rate of 7.0% and is expected to reach US$1.92 billion by 2030.

Technological upgrades must closely align with the needs of emerging industries:

New Energy and Automotive: The demand for lightweight materials and precision processing of battery components has driven explosive demand for high-precision die-cutting equipment. Circular die-cutters excel in multi-layer lamination and tight-tolerance rotary die-cutting of these materials.

Medical and Electronic Semiconductor: With the miniaturization of electronic products and the increasing sophistication of medical devices, high-power laser die-cutters have become the preferred solution for processing precision components.

Packaging: With the surge in demand for on-demand packaging and e-commerce customization, Haike’s digital die-cutting equipment is helping BoxMaker eliminate traditional die-cutting processes, enabling dynamic assembly production and shortening lead times by over 50%.

II. Diversified Market Development: Breaking Regional and Industry Boundaries

Emerging Market Layout

Against the backdrop of increasing US tariffs, traditional export models face rising costs and supply chain restructuring challenges. Leading companies are optimizing their global footprint through a “regional manufacturing hub + localized production” model:

The rise of manufacturing in Southeast Asia (Vietnam, Malaysia, and Thailand) has led to a surge in equipment demand.

Central and Eastern Europe and Mexico have become springboards for circumventing European and American tariffs.

BRICS capacity cooperation reduces policy risks.

Cross-industry penetration

Data from the South China International Die-Cutting Festival shows that die-cutting technology applications are expanding from consumer electronics to high-growth sectors such as new energy, medical, and automotive.

Medical: Growing demand for precision die-cutting of sterile materials.

New energy batteries: Die-cutting accuracy requirements for separators and electrodes are rising to ±0.1mm.

Automotive electronics: Exploding demand for die-cutting of smart cockpit components.

Companies need to overcome growth ceilings through customized industry solutions. For example, Delta ModTech’s Crusader system is designed for multi-layer lamination and die-cutting, meeting the precision processing requirements of automotive composite materials.

III. Precision Marketing and Digital Customer Acquisition: Data-Driven Customer Reach

Precision Online Traffic Generation

A case study of a Dongguan manufacturing company shows that by 2024, machinery companies using Google Ads will see an average customer acquisition cost reduction of 38% and a 35%+ increase in conversion rate. The key to success lies in:

Long-tail keyword matrix: Deploy targeted keywords such as “CNC die-cutting machine supplier” and “new energy material die-cutting solutions.”

Multi-platform integration: Covering Google Search, YouTube, and Gmail ad placements, reaching the entire purchasing decision-making process.

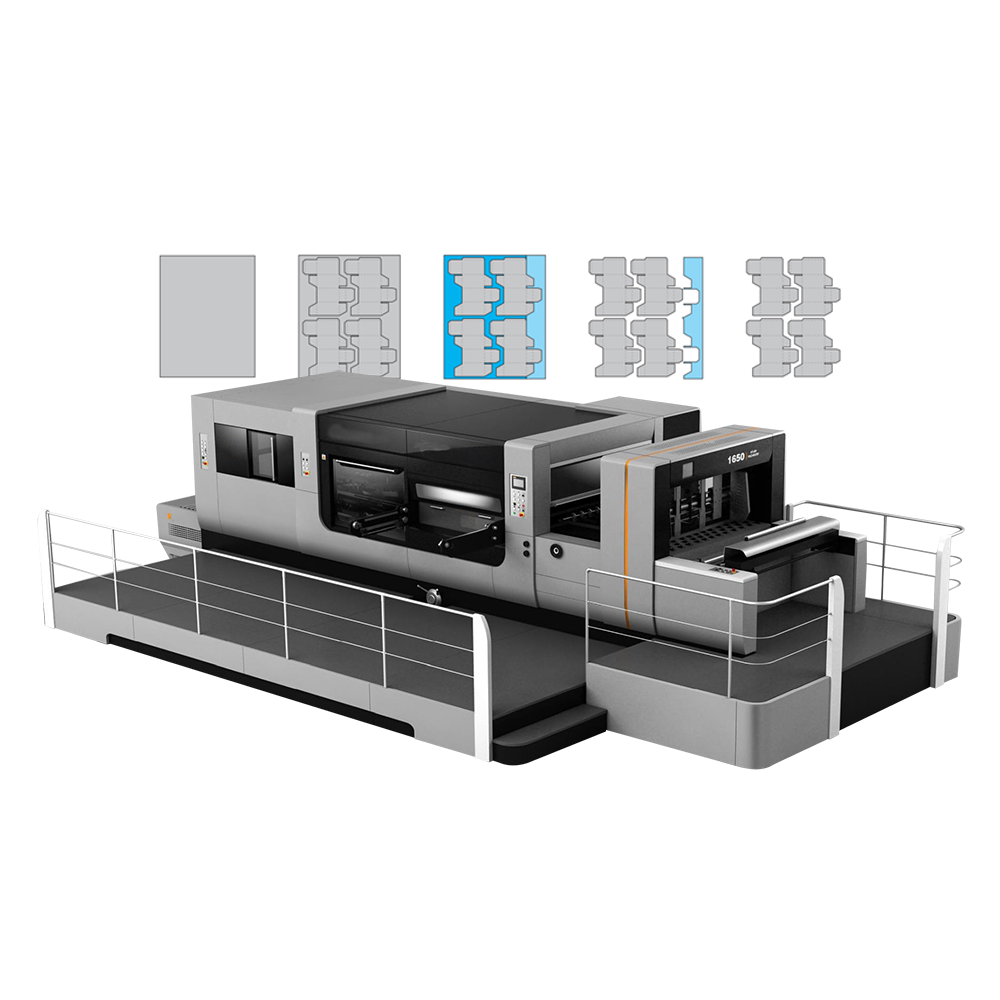

3D Technology Demonstration: Changan Automation Equipment Factory uses animations of equipment operating principles to enhance customer trust.

Social Media Marketing Upgrade

KAWO The 2025 B2B Social Media Marketing White Paper reveals:

75% of buyers prefer self-research, and 80% of decision-making information is obtained within the first five days of contacting a supplier.

Industrial equipment companies should adopt a three-tiered matrix: “official accounts + KOLs + interest-based accounts.”

Content strategies focus on scenario-based presentations: factory traceability live streams, real-life troubleshooting demonstrations, and online Q&A sessions with technical experts.

Data-enabled marketing.

Build a “social media-CRM full-chain tracking” system to achieve:

Dynamic attribution models quantify ROI across channels.

Customs data matches buyer lists for remarketing.

AI toolkits generate structured content (technical parameter comparisons/3D models).

IV. From Equipment Vendor to Solution Provider: Evolving the Value Proposition

The traditional equipment sales model has reached its ceiling, and leading companies are increasing customer loyalty through service-oriented transformation.

Technical Value-Added Services: ABG launches EcoLeaf digital technology, enabling metal decoration with self-adhesive labels, reducing customer material waste by 30%.

Software Ecosystem Building: Vivid launches Zip Core Packaging. Suite software optimizes the entire process from packaging design to production.

On-demand production: Haike’s digital die-cutting system uses AI-driven software to dynamically combine multiple operations, optimizing overall sheet material utilization.

The proportion of service revenue has become a key indicator of customer value for equipment companies. According to industry research, companies that provide full-cycle solutions have a 45% higher customer renewal rate than pure equipment sales companies.

V. Exhibitions + Ecosystem Synergy: Precision Exploitation of Offline Scenarios

Industry exhibitions remain a core platform for efficient customer acquisition. The 2025 South China International Die-cutting Festival will innovatively create a “exhibition + conference + festival” three-core driving model:

TAP Invited Buyer Program: Provides precise one-on-one matching with over 3,000 overseas professional buyers

Outlet Shopping Festival: Special equipment prices stimulate on-site transactions and accelerate purchasing decisions

Technical Forum Matrix: Covers cutting-edge topics such as new energy die-cutting processes and environmentally friendly materials

More innovative ecosystem synergies are taking shape:

The Greater Bay Area Industrial Expo and Tanji Technology have partnered to build an intelligent supply and demand platform, using AI to match upstream and downstream suppliers in the industry chain.

A full-chain service offering encompassing “lead mining – precise engagement – offline matching” addresses the pain point of information asymmetry in the industrial sector.

The die-cutting job fair simultaneously addresses the shortage of technical talent among clients.

The battle for customer acquisition in the automatic die-cutting machine industry has entered a three-dimensional era of “technology + scenarios + ecosystem.” On the technical side, circular knife and laser die-cutting are opening up new frontiers in the new energy and semiconductor sectors. On the market side, Southeast Asia and emerging industries are emerging as key drivers of success in overcoming tariff constraints. On the marketing side, data-driven, precise engagement and scenario-based content are reshaping the purchasing decision-making process. The future winners will be those companies that transform cutting processes into customer growth engines – those that can leverage AI to improve efficiency and use solutions to penetrate industry barriers, ultimately completing the value leap from “Made in China” to “Smart Manufacturing in China” on the global stage.