Die-cutting machine: the invisible engine of precision manufacturing, driving the upgrading of six industries

Die-cutting machine: the invisible engine of precision manufacturing, driving the upgrading of six industries

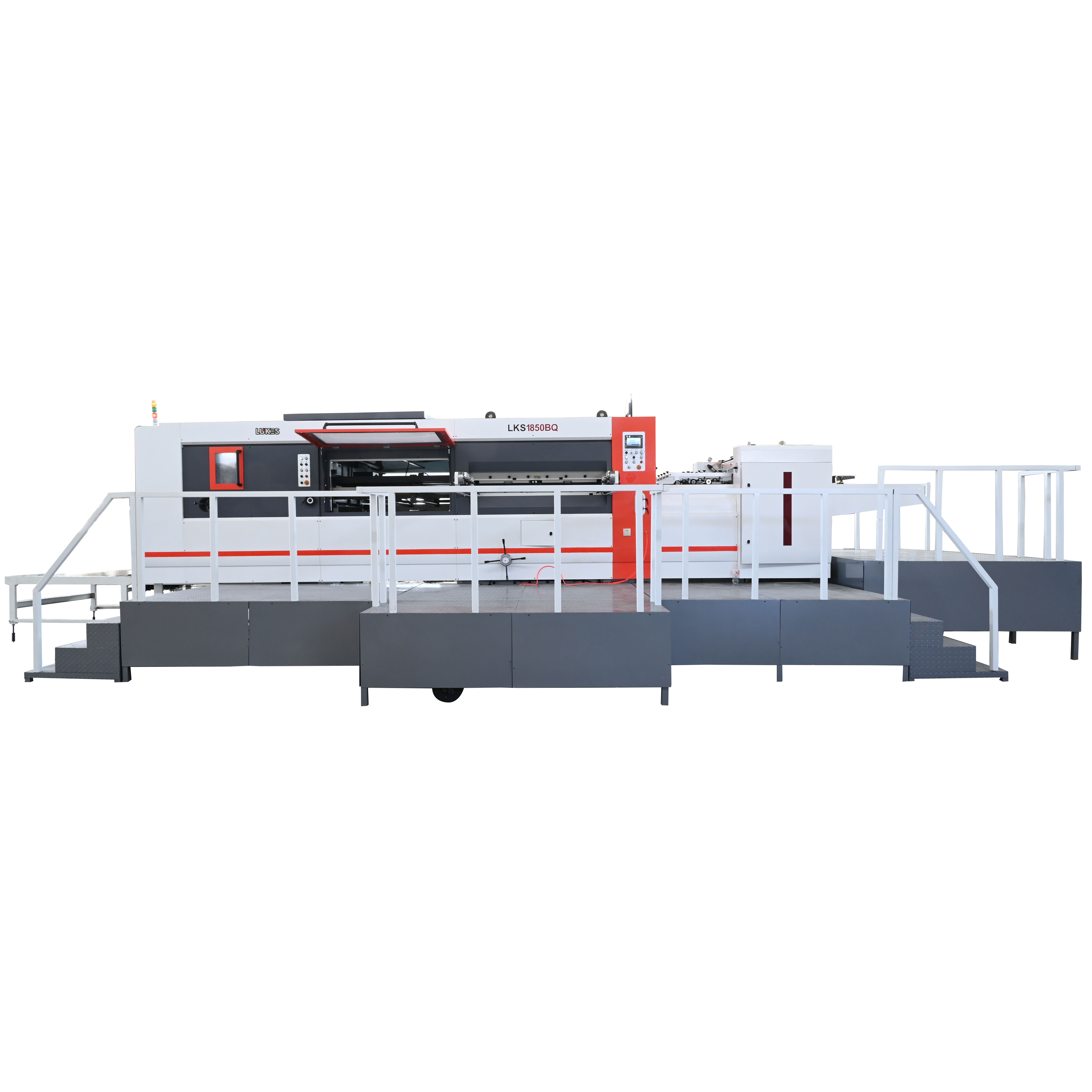

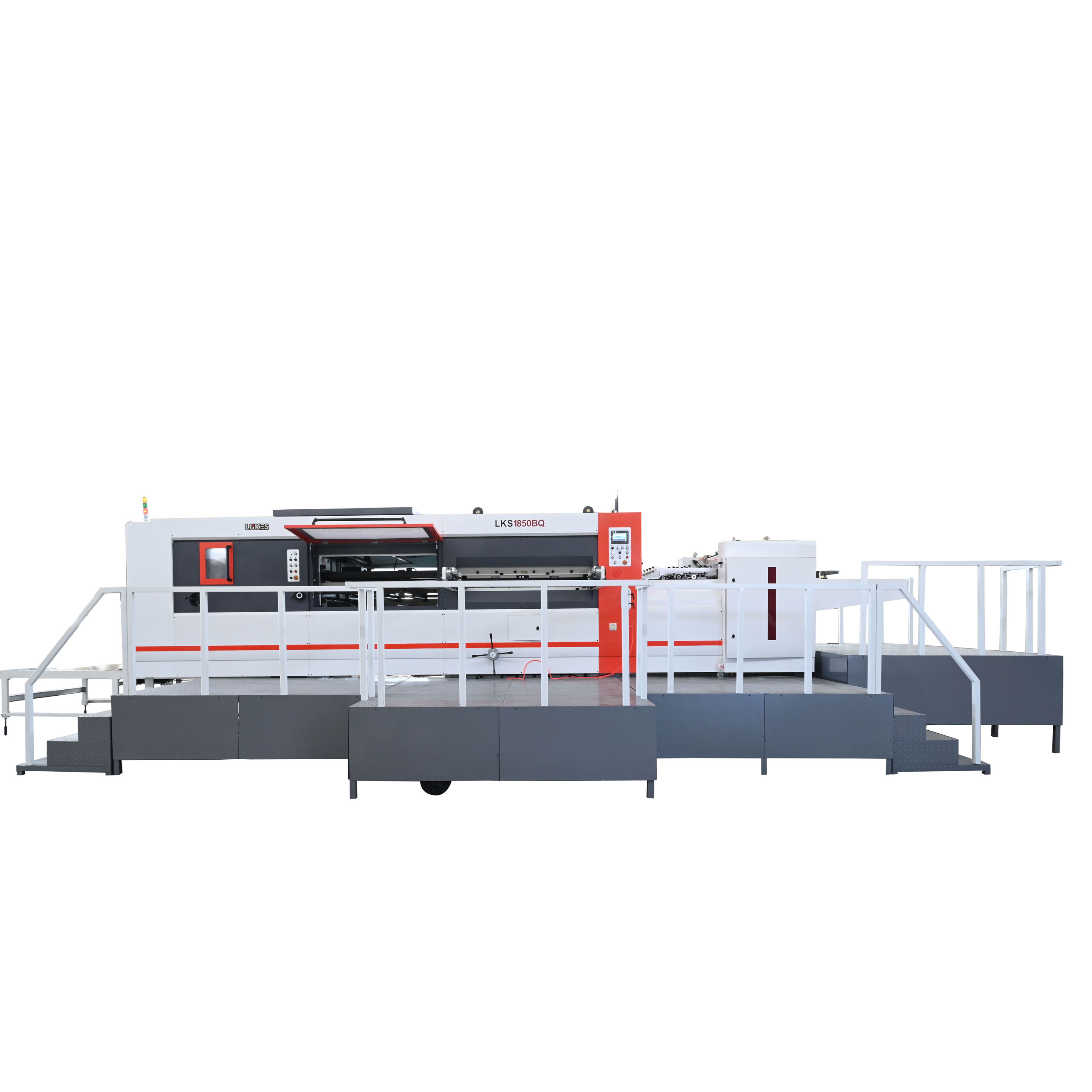

As a key equipment in modern manufacturing, die-cutting machine uses molds to perform high-precision cutting, creasing or punching of materials, and converts paper, plastic film, metal foil, composite materials, etc. into parts of specific shapes and sizes. With the iteration of technology, its application has penetrated from traditional printing and packaging to cutting-edge fields such as consumer electronics, new energy batteries, medical health, automobile manufacturing, and shoemaking industries, becoming the core force to promote the refined and efficient production of industries. The following details its in-depth application scenarios and technical value in six major industries.

1. Packaging and printing industry: the “cutting master” behind the explosion of e-commerce

As the most mature field of die-cutting machine application, packaging and printing occupy a dominant position in the market. In 2023, the number of packaging and printing enterprises above designated size in China reached 10,441, and the total output value of the industry exceeded 1.47 trillion yuan24. The core value of die-cutting machine here lies in:Customized production: Efficiently complete the precise cutting and creasing of special-shaped paper boxes, anti-counterfeiting labels, and gift box structures to meet brand differentiation needs Automation efficiency: Linked printing lines to achieve roll-to-roll die-cutting, with a processing speed of hundreds of times per minute, greatly reducing labor costsE-commerce supporting explosion: With the surge in express parcel volume, the demand for die-cutting of corrugated boxes and cushioning liners has grown exponentially, becoming a new engine for the industry48

2. Consumer electronics industry: “precision scalpel” for micro components

In the thin and light electronic devices Under the trend of globalization, precision rotary die-cutting machine have become the core equipment for producing electronic adhesive parts:Component applications: dust screens, screen foam, battery glue, thermal conductive graphite sheets and other micron-level components in smartphones/tablets rely on high-precision die-cuttingTechnological breakthrough: Through independent servo control systems and CCD visual positioning, one-time die-cutting of multi-layer composite materials (such as copper foil + adhesive layer) is achieved, and the tolerance is controlled within ±0.05mmCost advantage: Compared with traditional stamping, the rotary die-cutting speed is increased by more than 3 times, the material utilization rate exceeds 95%, and it is significantly reduced Low manufacturing cost of high-end components such as FPC (flexible circuit board)16

3. New energy battery industry: the biggest winner of the explosion of laminated batteries

As power batteries shift from winding to lamination, the demand for die-cutting machine has seen explosive growth:Core application: Pole cutting is a key link in the production of laminated batteries. It is necessary to accurately cut the positive and negative poles into rectangles or special shapes (such as Honeycomb Energy’s “short knife battery”) and process the diaphragm/electrolyte materials Equipment upgrade: The winding die-cutting machine realizes one-time forming of the pole ear, and cooperates with the asynchronous tension system to reduce pole wrinkles and improve yield To more than 99% Market space: In 2022, the market size of lithium battery die-cutting machines in China will reach 4.12 billion yuan. It is expected that the production capacity of stacked batteries will exceed 300GWh in 2025, giving rise to a demand for equipment worth tens of billions of yuan 310

4. Medical and health industry: “double champion” of safety and flexibility

The medical field has strict requirements on material safety and processing cleanliness, and die-cutting technology provides key support:Product coverage: Forming and processing of multi-layer composite sanitary materials such as Band-Aid hydrocolloid layer, plaster cloth drug-loaded film, medical gauze, and infusion patch Technical advantages:

▶ Dust-free workshop compatibility: closed die-cutting unit avoids contamination

▶ Flexible production: fast mold switching to adapt to small batch and multi-variety orders (such as customized dressings)

▶ Zero-damage cutting: circular knife die-cutting protects the fiber structure and ensures product permeability and liquid absorption performance16

5. Automobile manufacturing industry: “new battlefield” from interior parts to electrification

The demand for die-cutting machine in the automotive industry is dual-track:Traditional applications: three-dimensional curved cutting of interior parts such as leather seats, steering wheel covers, and instrument panel soft pads Electrification increment:

▶ Large-scale production of battery pack insulation gaskets and thermal conductive silicone pads

▶ Precision cutting of motor electromagnetic shielding materials

▶ Fully automatic die-cutting of optical adhesive (OCA) for on-board display screens19

6. Shoemaking industry: “flexible productivity” in the era of personalization

In shoe manufacturing, die-cutting machine are transforming from mass production to small-batch customization:Efficiency revolution: Leather and synthetic materials are cut into uppers, linings, and insoles at one time, which is 5-8 times more efficient than traditional knife dies Technology iteration: Laser die-cutting machine achieve contactless processing of complex hollow patterns (such as sports shoe meshes) to avoid material deformation9 Future trends: Intelligent and green manufacturing go hand in hand

Die-cutting technology is undergoing four major upgrade directions:

Intelligent integration: Real-time monitoring through AI visual inspection + IoT data Adjust cutting parameters to increase yield by 30%

Multifunctionality: a single device integrates die-cutting, printing, hot pressing, and quality inspection processes, reducing production line configuration by 15

Energy-saving design: using servo motor dynamic power adjustment, energy consumption is reduced by 40%; the use rate of environmentally friendly materials reaches 80%1

Customized service: from equipment specifications to cutting tools, full-process customization is supported to meet the manufacturing needs of small batches and fast iterations48