The Intelligent Revolution in the Die-Cutting Machine and the Secrets to International Market Transformation: Trends and Practical Strategies

The Intelligent Revolution in the Die-Cutting Machine and the Secrets to International Market Transformation: Trends and Practical Strategies

At two o’clock in the morning, Shanghai OPEC Machinery’s Alibaba International Marketplace store received an inquiry from a Saudi Arabian buyer. An AI assistant responded immediately, and after five rounds of professional conversation, it fully captured key information such as the equipment’s purpose and logistics requirements. The next morning, General Manager Xu Jingqian reviewed the customer profile compiled by the AI and quickly followed up, ultimately securing a 140 million yuan Middle Eastern order. The fully unmanned AI reception process was a key catalyst for this deal.2 This real-world case reveals the technological revolution and new market opportunities currently underway in the die-cutting Machine industry.

I. The Intelligent Transformation Wave in the Die-Cutting Machine Industry

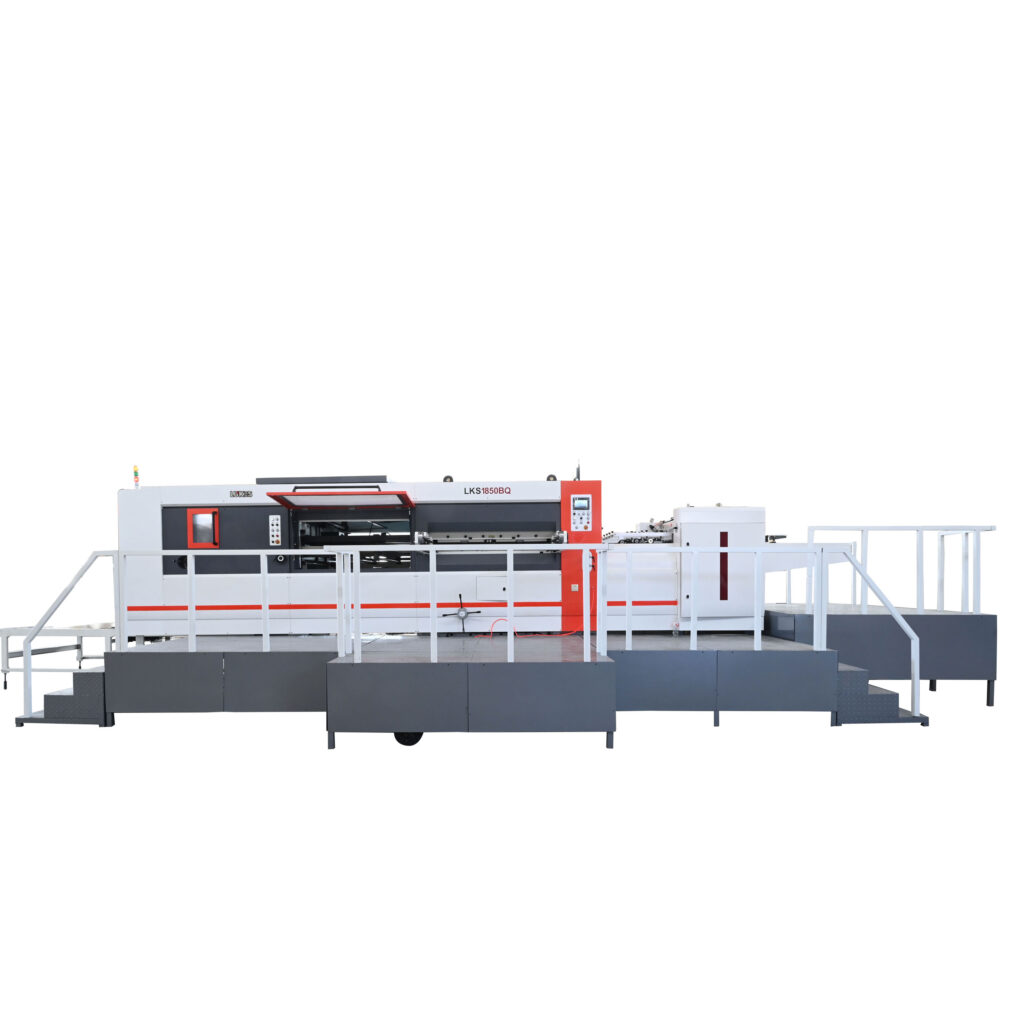

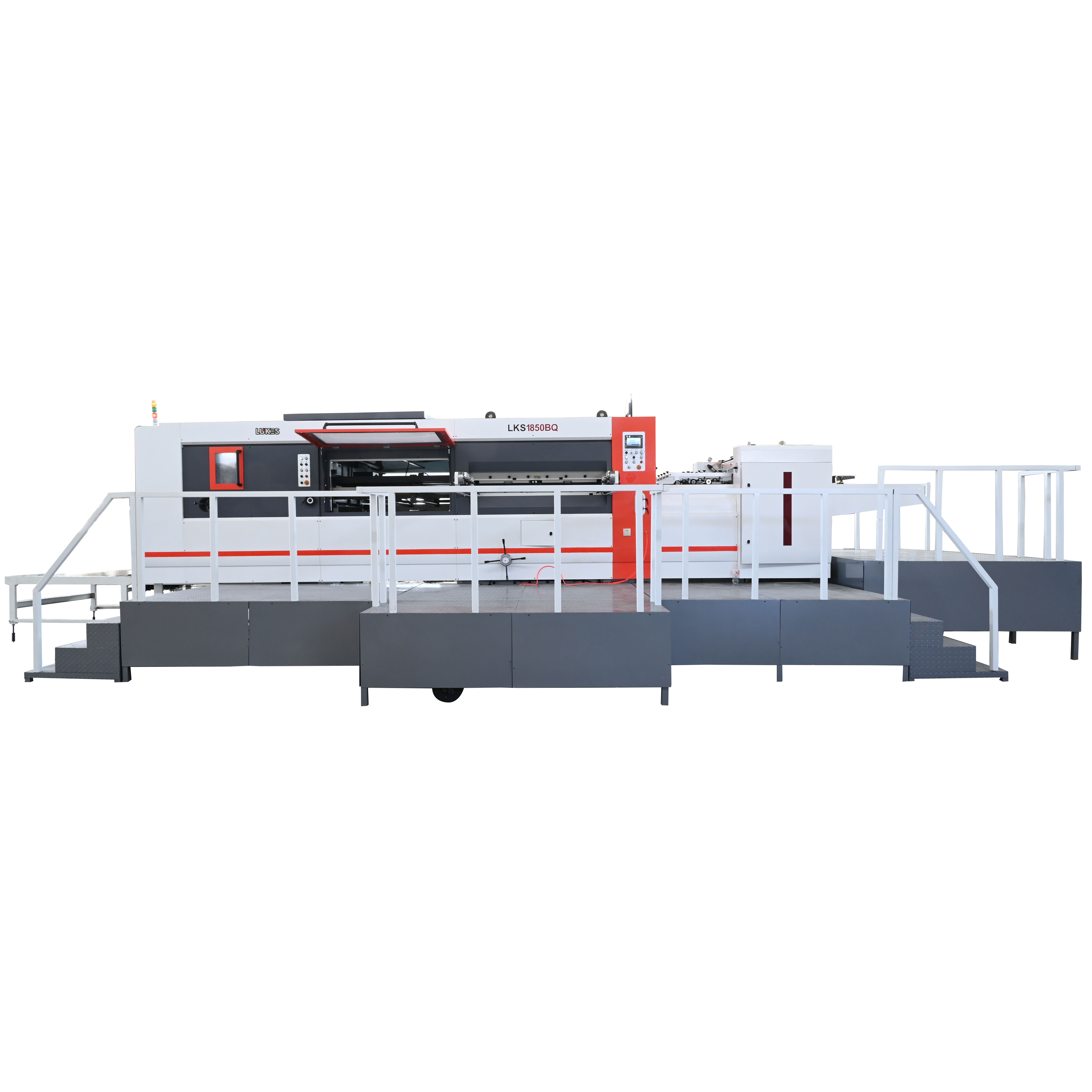

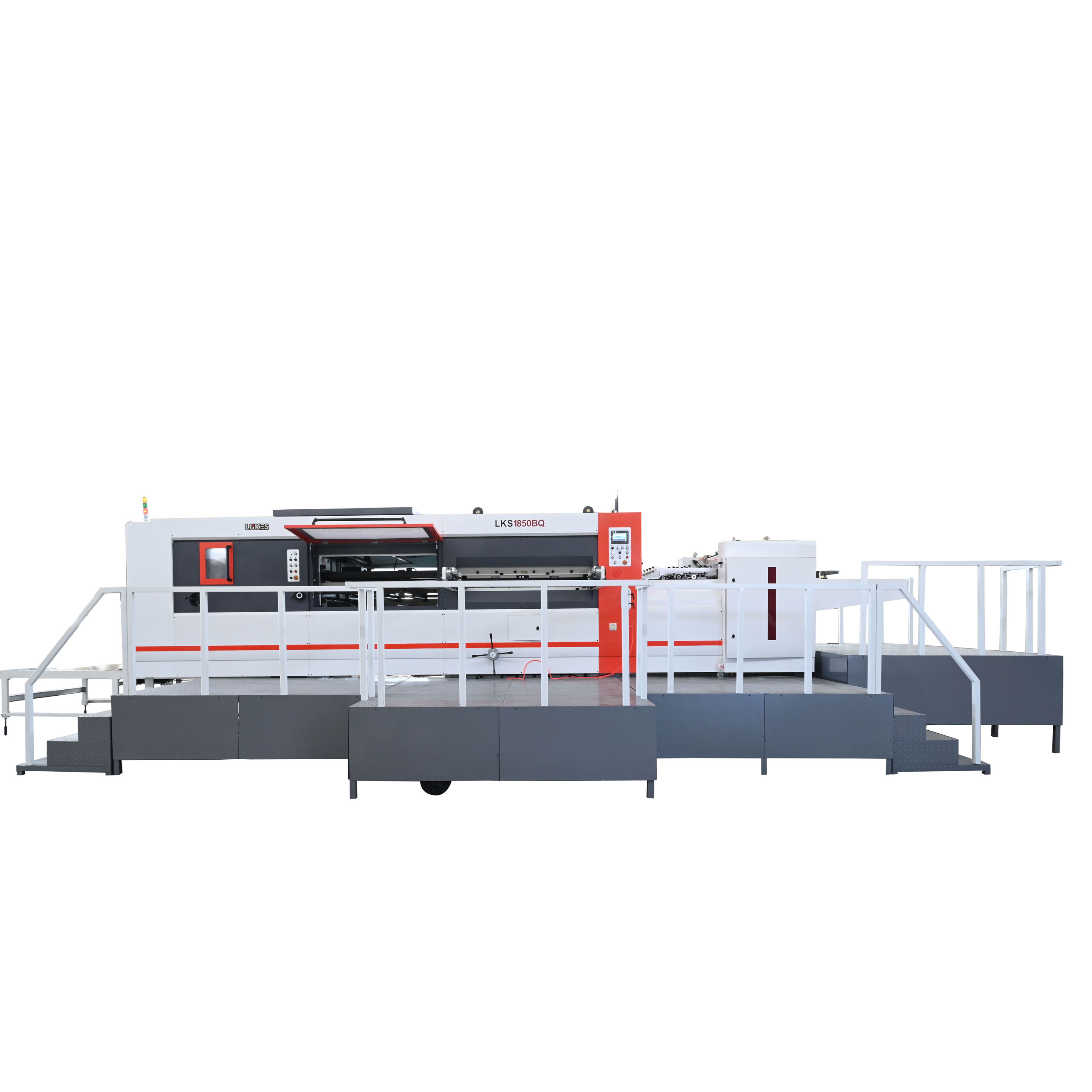

Die-cutting equipment, as core equipment in paper processing and packaging production, is undergoing a transition from traditional machinery to intelligent manufacturing. As labor costs continue to rise, precision rotary die-cutting equipment, with its high production efficiency and compact footprint, is rapidly replacing traditional flat-blade die-cutters. In the consumer electronics sector, it can precisely cut adhesive components in mobile phones; in the medical field, it can efficiently process composite materials such as medical patches and Band-Aids.

The in-depth application of AI technology has become a watershed for the industry:Intelligent inspection systems: Using machine vision to identify defects such as burrs and dimensional deviations in real time, they increase product qualification rates by over 30%.Predictive maintenance: Analyzing equipment operating data provides early warning of failures, reducing unplanned downtime and extending equipment life by 20%.Flexible production control: For example, Shuangyi Optoelectronics’ newly patented intelligent die-cutting system integrates ±0.02mm high-precision visual positioning, enabling one-click die changeovers. This has increased production capacity by 89% and reduced changeover time to 5 minutes.Global market data confirms this trend: Sales of automatic laser die-cutting equipment are expected to exceed US$1 billion by 2031, with a compound annual growth rate of 6.7%. As the largest producer, China’s die-cutting equipment market reached 23.7 billion yuan in 2023 and is expected to grow to 26 billion yuan in 2024.

II. International Market: How AI Drives a Boost in Conversion Rates

For export companies, Alibaba International Market has become a core channel for order conversion. However, traffic does not equal sales; a systematic operational strategy is the key. Recent data reveals the astonishing effectiveness of AI tools:

AI-optimized product conversion rates increased by 52%

AI-assisted customer service response rates increased by 36%

AI-driven product success rates increased by 29%, reducing the time required to create blockbuster products by nearly one-third

The “High-Quality Blockbuster Product” matrix is the core weapon for international site operations. High-value products certified by the platform possess three key characteristics:

Traffic acquisition capacity is 195 times that of ordinary products.

Payment conversion rate is 6 times that of ordinary products.

Developing such products requires three key breakthroughs:

Precise keyword analysis: Focus on word sources with stable search indexes, reasonable click-through rates, and a strong match with the primary country of sale, while dynamically eliminating inefficient keywords.

In-depth buyer profiling: Focus on targeting high-value L3+ customers (who prefer large orders and high-priced customization), and offer premium placements in high-conversion regions like Europe and the United States.

Scenario-based service tags: Adding the “Overseas Spot” tag can increase conversion rates for European and American orders by 192%; orders for “European Quality Certified” certified products increased by 38% year-on-year.

The 100 million yuan order from Shanghai OPEC perfectly illustrates this strategy. AI not only handles late-night inquiries but also identifies high-potential customers through specialized question design, laying the foundation for subsequent transactions.

III. Future Key Winning Factors: Full-Chain Intelligence and Green Manufacturing

Industry competition has entered a new dimension. The country’s “14th Five-Year Plan for Intelligent Manufacturing” explicitly mandates that by 2025, more than 70% of manufacturing enterprises must achieve digitalization and networking. This is driving the development of die-cutting equipment in three key directions:

Multifunctional integration: Integrating die-cutting processes with hot pressing, printing, and embossing to meet the needs of emerging sectors such as new energy vehicle interiors and medical composite materials.

Energy conservation and carbon reduction: Using variable-frequency motors and load-adaptive systems, such as Shuangyi Optoelectronics’ solution, reduces overall energy consumption by 18%.

Digital twinning: Mirroring equipment operating data for modeling enables preventive maintenance and parameter self-optimization.

The intelligentization of foreign trade is also deepening. The logistics visualization platform jointly developed by Maersk and Alibaba International Station has achieved full-process tracking. Combined with an AI-powered tariff engine, it dynamically optimizes customs clearance solutions, reducing cross-border costs by 10%. When production lines and foreign trade chains are restructured by AI, even small businesses can possess the strategic capabilities of top-tier foreign trade teams.

Conclusion: Opportunities on the Cutting Edge

When Shuangyi Optoelectronics redefines cutting standards with 0.02mm precision, and when late-night AI conversations generate hundreds of millions of orders, the competitive rules of the die-cutting machine industry have been rewritten. The industry’s projected size, exceeding 26 billion yuan by 2025, will be driven by companies that simultaneously pursue intelligent equipment and digital foreign trade.Visual sensors on production lines, AI-powered shopping guides in international stores, and tariff optimization algorithms in logistics systems—these technological nodes are connecting to form a new chain of competitive advantage. Over the next five years, the industry may witness a deep integration of intelligent equipment manufacturers and end-to-end data-driven traders. The key to success lies in every algorithm and every transformation being implemented.