Fully Automatic Die-cutting Machine Technology: The “Invisible Engine” Driving Global Industrial Upgrading

Fully Automatic Die-cutting Machine Technology: The “Invisible Engine” Driving Global Industrial Upgrading

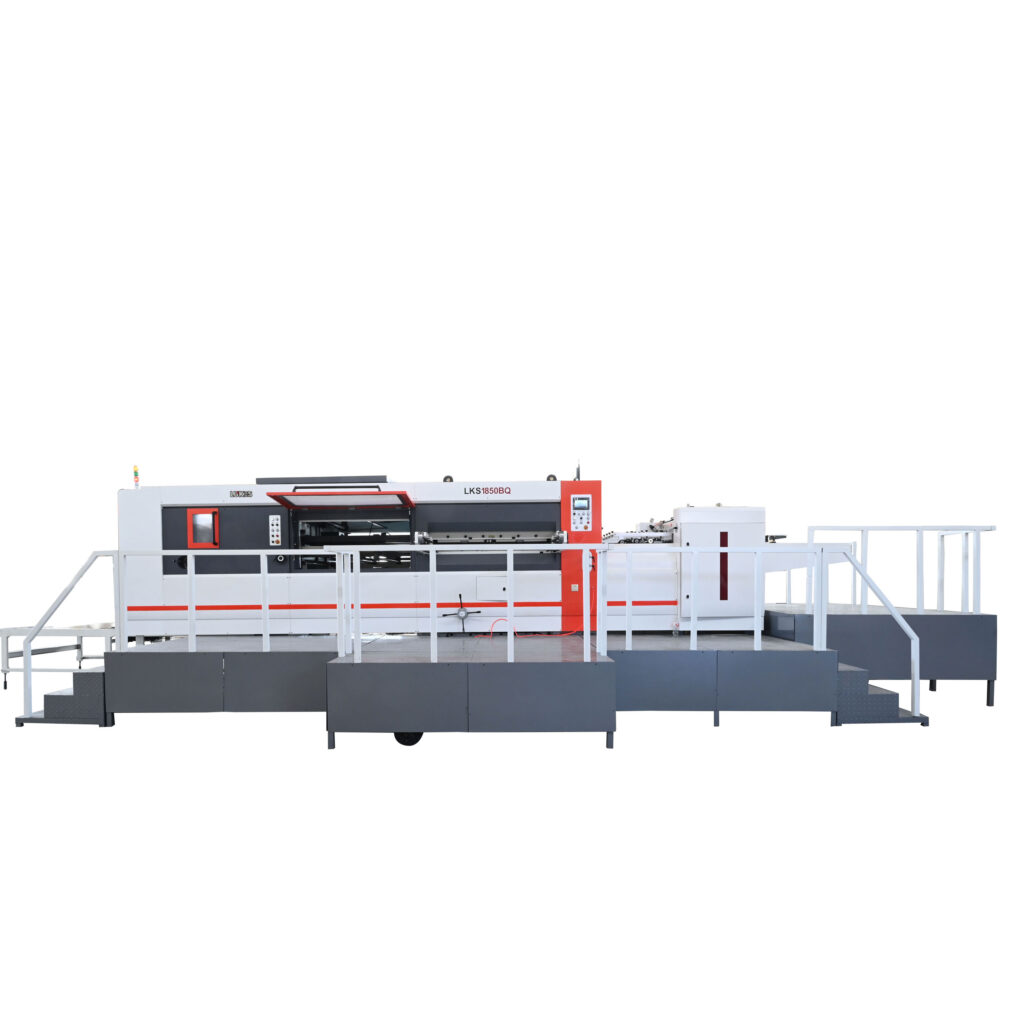

In our daily lives, from the perfect opening and closing of mobile phone boxes, the three-dimensional embossing of book covers, to the precision insulation materials of new energy vehicle batteries, die-cutting technology, like a silent craftsman, shapes the exquisite details of modern life. The emergence of fully automatic die-cutting machine has pushed this traditional craft to new heights of intelligence and efficiency.

I. Fully Automatic Die-cutting Machine: Reshaping the Four Core Values of Manufacturing

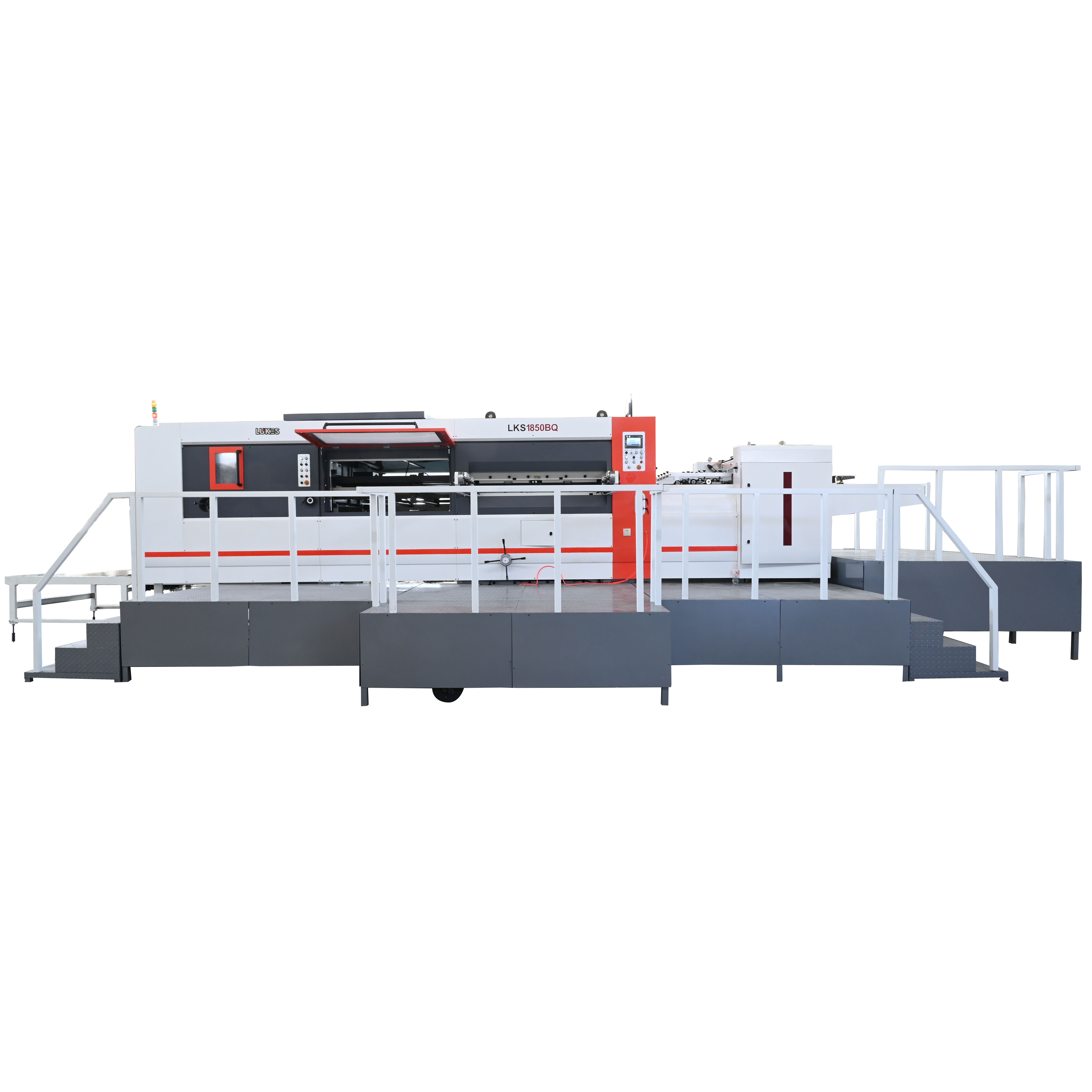

A Dual Revolution in Efficiency and Precision Traditional die-cutting relies on manual tool adjustment and empirical control, while fully automatic die-cutting machine have achieved a qualitative leap through CNC systems and machine vision. Take Shuangyi Optoelectronics’ vision alignment system, for example. It captures product images in real time and automatically calibrates cutting positions, controlling processing errors to the micron level, increasing production efficiency by over 40% and reducing defect rates from 3% to 0.5%. In the packaging industry, this means 30 square meters of high-precision cutting can be completed per hour, operating 24 hours a day.

Cost Savings and Democratizing Small-Batch Production Changzhou Temine’s A-Starcut digital plateless Fully automatic die-cutting machine has completely overturned traditional production practices. It enables on-demand die-cutting without platemaking, reducing costs for small-batch orders by nearly 50%. It is particularly suitable for the production of personalized packaging and limited-edition cultural and creative products. This flexibility enables small and medium-sized businesses to undertake high-end custom orders. One stationery company used this technology to reduce the lead time for customized notebooks from 14 days to 3 days, and customer complaints dropped by 90%.

Green Transformation of Materials and Energy The high-precision processing of fully automatic die-cutting machine significantly reduces material waste. Nanjing Aide Printing used an intelligent die-cutting system to reduce the size and weight of the seventh edition of the “Cihai” (Encyclopedia of Chinese) from eight volumes to two, saving forest resources and reducing logistics carbon emissions.6 Furthermore, LED-UV curing technology replaces traditional drying, reducing energy consumption by over 30% and VOC emissions by 99%.

An Innovation Engine for Cross-Border Applications From cutting breathable holes in medical hemostatic patches to forming micropores in power battery separators, fully automatic die-cutting machine have pushed the boundaries of traditional printing and packaging. Laser die-cutting technology is thriving in the new energy sector—its non-contact cutting method avoids damage to lithium battery electrode materials, increasing product yield to 99.5%. Voith Paper’s newly developed “four-roller, three-press belt, center-roller belt” technology achieves integrated, efficient production from papermaking to die-cutting.

II. Global Reach: Two-Track Expansion in Technology and Market

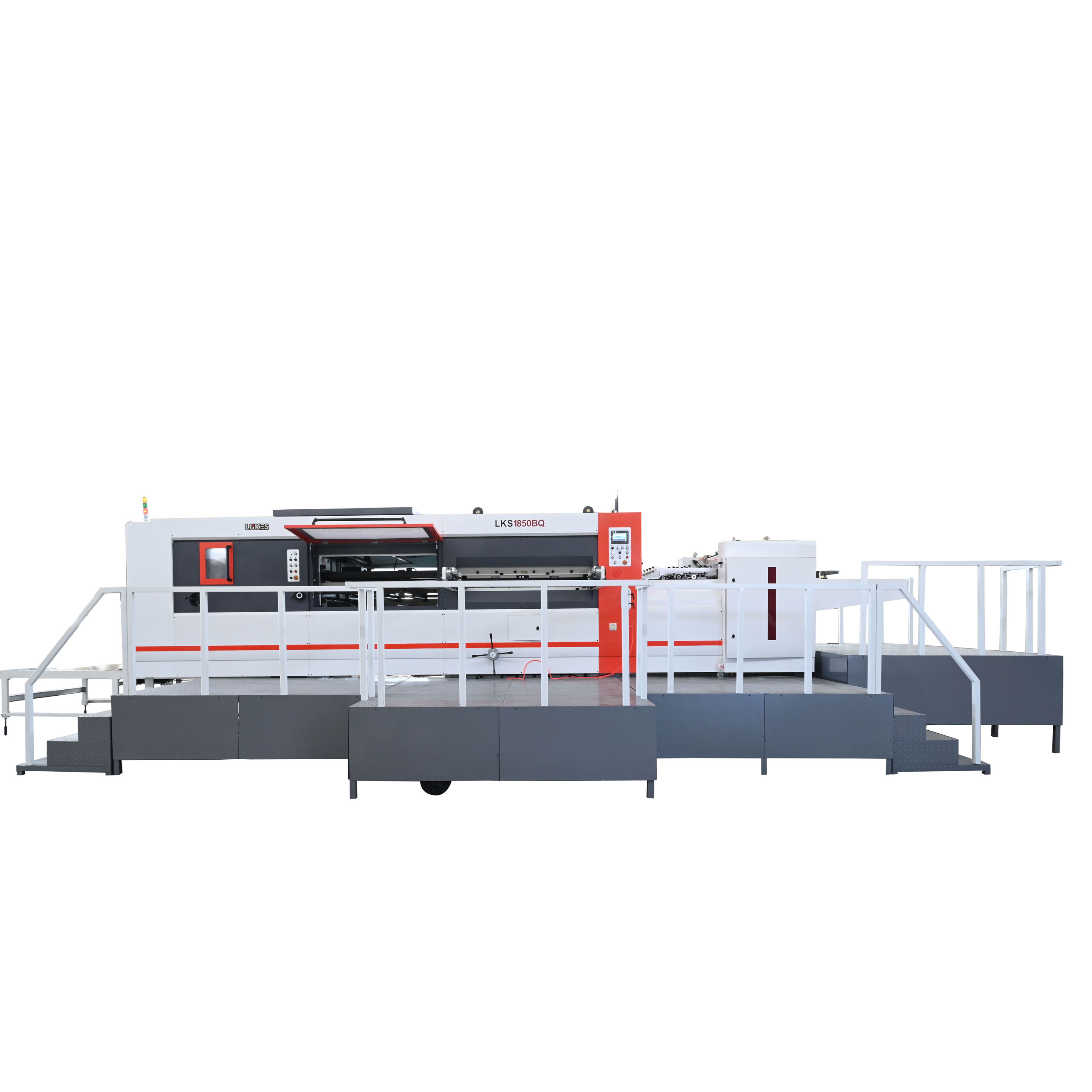

In-Depth Analysis of Regional Market Landscapes According to QYResearch data, the global flatbed digital Fully automatic die-cutting machine market will reach US$449 million in 2024 and is expected to exceed US$580 million in 2031, with a compound annual growth rate of 3.7%. Automated laser die-cutting equipment, however, will experience even faster growth, with a CAGR of 6.7% over the same period, and the market size will leap from US$638 million to US$1.006 billion. In Europe and the United States, established companies like BOBST and Heidelberger hold a 60% share of the high-end market. Their equipment integrates AI quality inspection and predictive maintenance systems, resulting in a downtime rate of less than 0.5%. Meanwhile, China is breaking new ground with “smart manufacturing”: Han’s Laser’s laser die-cutting machines have successfully entered Tesla’s supply chain; Shanghai Yawei’s automatic die-cutting machines have an 18% market share in Southeast Asia.

In the electronics industry, fully automatic laser die-cutting has become standard for flexible circuit board (FPC) production; the medical field relies on it to cut the vent arrays in medical patches. More notably, the integration of digital printing and Fully automatic die-cutting machine has created a new business model. Wuzhou Special Paper has achieved zero inventory for book printing through a “pre-sale crowdfunding + on-demand production” model.

III. Technological Frontiers: Three Evolutionary Directions for Next-Generation Die-Cutting Machines

Digital Twins and Flexible Production Leading companies have begun deploying Fully automatic die-cutting machine digital twin systems, simulating and optimizing parameters in a virtual environment to increase material utilization by another 5%. Germany’s Sanwa’s latest model supports cloud-based storage of 1,000 product parameters, allowing switching orders with a simple QR code access.

Composite Processing Integrating Multiple Technologies Water jet and laser composite Fully automatic die-cutting machine can now process materials ranging from 0.1mm to 50mm thick, ranging from food packaging paper to carbon fiber composites. Delta ModTech’s Hybrid series integrates the entire “printing-die-cutting-quality inspection” process, with customers reporting an 18% reduction in overall waste.

A Green and Intelligent Industrial Revolution Nanjing Aide Printing’s Phase II smart factory integrates Fully automatic die-cutting machine with a photovoltaic energy storage system, with solar power accounting for over 40% of power during the day. The AI-powered energy optimization algorithm incorporated into the equipment reduces energy consumption per ton of paper processed by 15%. This “green and intelligent manufacturing” model is becoming a new industry standard.

Fully automatic die-cutting machine have quietly become the “precision neurons” of the global industrial network. In North America, they power iPhone packaging lines that produce 20,000 boxes per hour; in Southeast Asia, they help small workshops become certified suppliers of Nike shoe boxes; and in Norway, they even help cut marine-degradable fishing net materials. This seemingly traditional machine is evolving at a rate of 10.6% per year, becoming increasingly intelligent, driving the transformation of industries from book paper to new energy batteries.46 When future historians write about the 21st-century manufacturing revolution, the automation upgrade of Fully automatic die-cutting machine is destined to be a subtle and crucial chapter.