How does an 1850 fully automatic die-cutting machine pave the way for industry transformation?

When the Efficiency Revolution Meets Flexible Production

How does an 1850 fully automatic die-cutting machine pave the way for industry transformation?

I. Global Market Expansion and the Strategic Positioning of the 1850

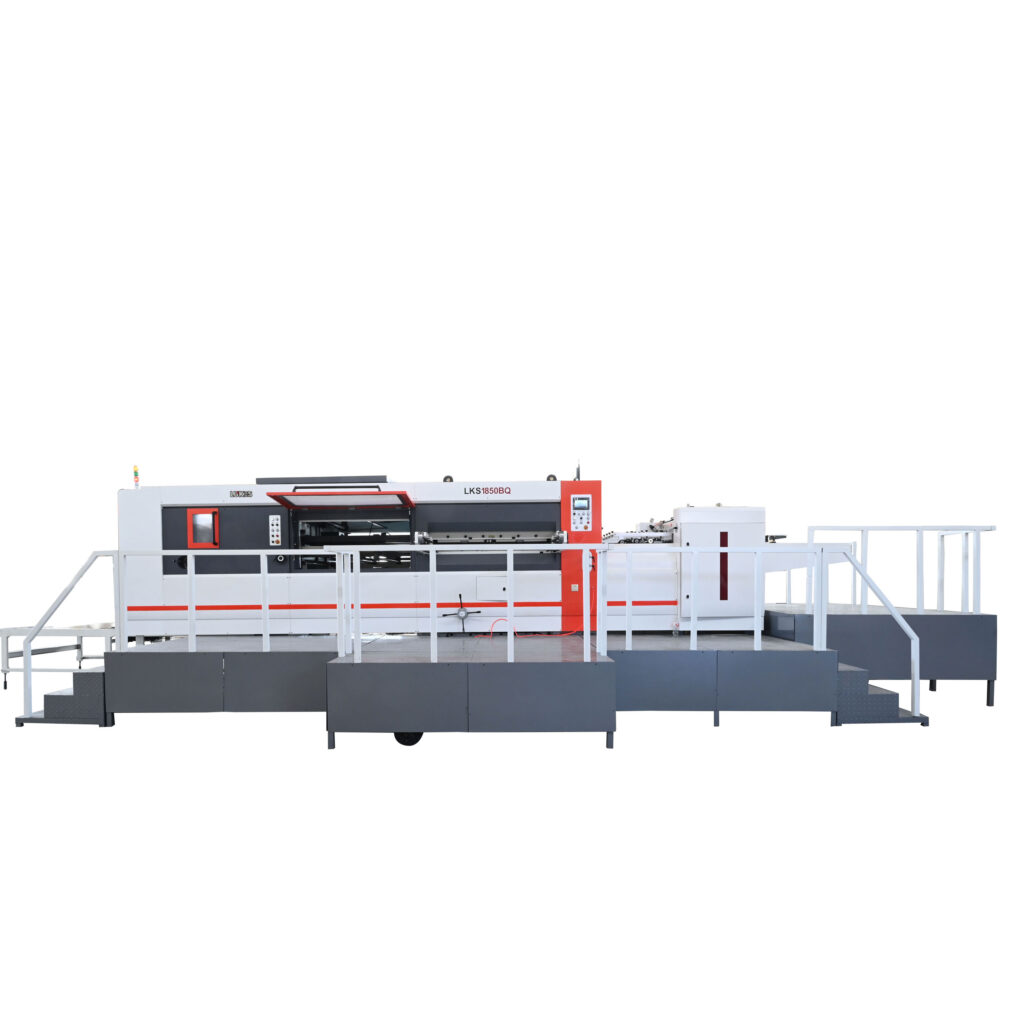

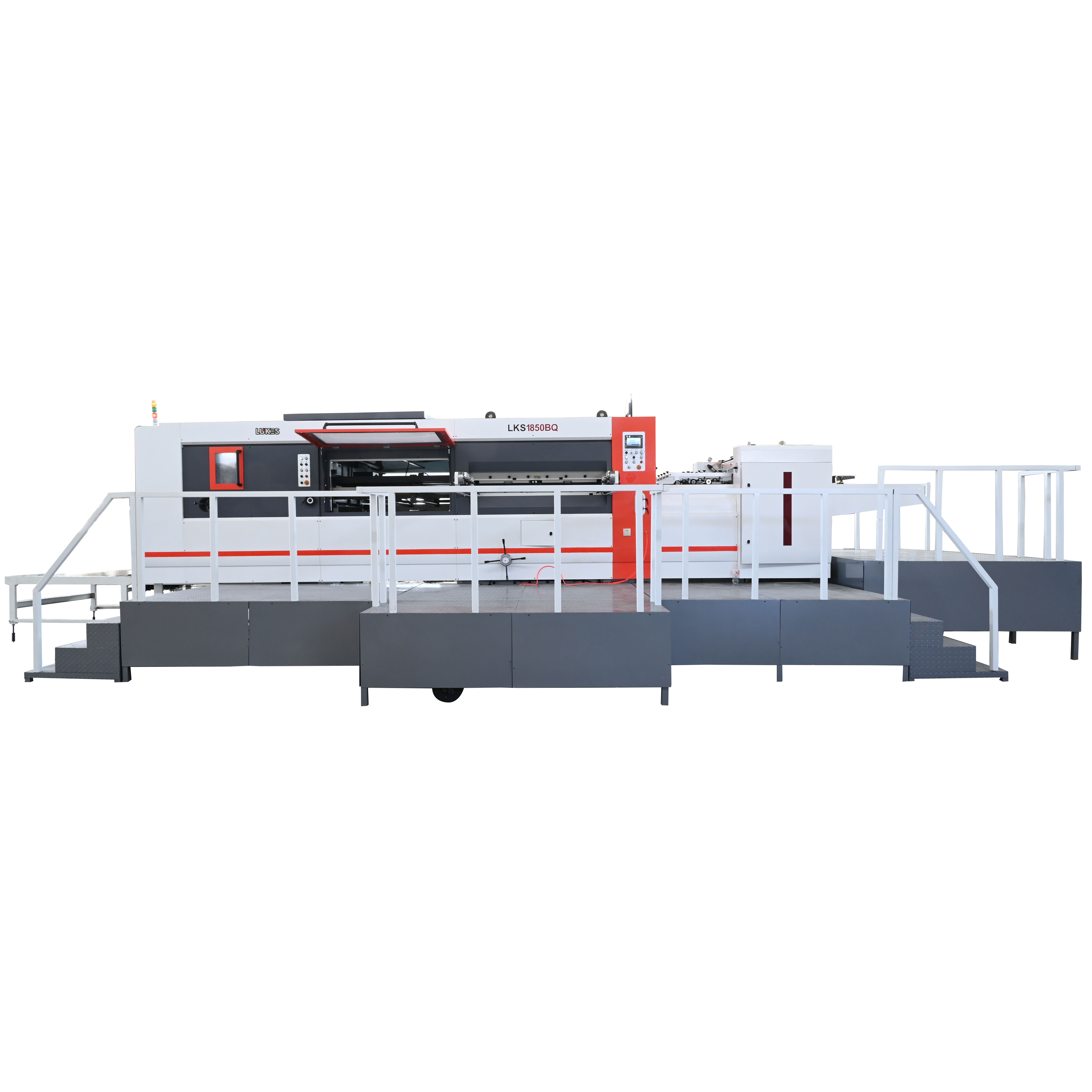

The global die-cutting equipment industry is experiencing structural growth. By 2024, the global automatic die-cutting equipment market was projected to reach US$638 million, with a compound annual growth rate of 6.7% on its way to US$1.006 billion by 2031. Although the specific share of the Chinese market has not been disclosed, it has become a growth engine. By 2024, domestic demand for die-cutting equipment will reach 180,000 units, with a market size exceeding 26 billion yuan.710 Against this backdrop, the 1850 fully automatic die-cutting machine, with its maximum processing width exceeding 1850mm (for example, the LKS1850Q’s die-cutting dimensions reach 1850 x 1400mm), is positioned for medium- and large-scale industrial production. Its advantages are:Strong compatibility: can process corrugated cardboard, cardboard (thickness 1-9mm) and composite materials6;Precision assurance: ±0.5mm die-cutting tolerance6, meeting the needs of precision packaging;Scale benefits: maximum mechanical speed of 3000 pieces/hour6, significantly reducing unit costs. This type of equipment targets large-scale, multi-material order production, filling the market gap between traditional flat knife die-cutting machines (small batches) and ultra-high-speed laser die-cutting machines (high investment).

II. Who is buying the 1850 fully automatic die-cutting machine? Portraits of three core customer groups

(1) Packaging and printing companies: those who have a strong demand for large-scale production The packaging industry is the largest application area for die-cutting equipment. In 2023, there were more than 10,441 packaging and printing companies above a certain scale in China, with a total output value of 1.47 trillion yuan. The explosive growth of e-commerce and logistics has driven massive demand for cartons. Typical requirements for these companies purchasing the 1850 automatic die-cutting machine include:Efficiency upgrade: For example, the Guangdong Yuexin K7 machine, through its “servo pressure-free paper feeding + intelligent order change system,” reduces order change time to 3 minutes, adapting to the increasing number of single-order orders;Cost control: Automatic paper collection and waste removal reduce manual labor by 30%;6 Large-size production capacity: Supports the production of cartons ranging from 1200mm to 2400mm (such as large appliance packaging for e-commerce).Representative customers: Chengdu Zhongtian Chengxin Packaging and Dongguan Yaoshun Packaging have already implemented intelligent die-cutting lines in large quantities.

(2) Electronics and medical manufacturers: the hidden demand for precision materials The demand for precision die-cutting in the consumer electronics and medical fields is surging:

Electronic products: Precision cutting of adhesive components and thin film circuit substrates inside smartphones/tablets requires equipment with ±0.1mm accuracy (CCD positioning system is required as an option);Medical consumables: Die-cutting of multi-layer composite materials such as plasters and band-aids requires avoiding contamination and ensuring smooth edges8.Such customers usually choose multi-functional integrated models, such as adding hot pressing and cleaning units to the 1850 model to achieve “one mold, multiple effects”.

(3) Export-oriented factories: Pioneers of international compliance The Southeast Asian and Indian markets are becoming new battlefields for Chinese equipment manufacturers. For example, an Indian packaging company recently purchased Guangdong Yuexin K7 equipment. Key drivers included:Cost sensitivity: Used 1850 models are only 40%-60% of new ones (approximately 260,000-560,000 RMB per unit).Environmental compliance: Required to comply with EU CE or North American UL energy efficiency standards, the new generation 1850 models feature energy-saving motors and intelligent power regulation systems.

III. Technological Iteration Direction: The Evolutionary Path of the 1850 Model

▶ Intelligence: From “Mechanical Control” to “Data-Driven”

Improved Adaptability: For example, PLC programming automatically compensates for pressure fluctuations (Shandong Lukes models are equipped with Siemens PLCs).

Predictive Maintenance: Real-time monitoring of tool wear and early warning, reducing downtime losses.

▶ Multifunctional Integration: Production Line Convergence is a Trend

Leading companies have launched “die-cutting +” composite machines, such as:Printing and Die-cutting All-in-One Machine (Yuexin K7) Die-cutting and Folder-gluing Line (supporting production of Taobao cartons as small as size )

▶ Green Manufacturing: Energy Saving and a Materials Revolution

Energy Consumption Optimization: Variable-frequency motors reduce standby power consumption by 30%;Environmentally Friendly Materials: Water-based paint finishes and recyclable packaging are added bonus points in international bids.

IV. Competitive Landscape: Local Brands’ Breakthrough

The Chinese die-cutting equipment market is showing a differentiated trend:

First Tier: Listed companies such as Tianjin Changrong Technology and Guangdong Dongfang Precision Machinery focus on high-end fully automatic lines;

Second Tier: Shandong Lukos and Guangdong Yuexin, focusing on mid-range 1850-type equipment with outstanding cost-effectiveness;

International Competitors: Swiss BOBST and Italian BIKO MECCANICA dominate the high-end market, but their prices are over 40% higher than domestic equipment.

The key advantages of domestic 1850-type equipment include:

Customized Service: Adjustment of paper feed speed and pressure parameters based on customer order specifications;

Localized Response: after-sales support (Yuexin promises an engineer on-site within 48 hours).

V. Future Outlook: The Growth Flywheel of the 1850 Machine

As manufacturing evolves toward flexible and zero-waste production, the 1850 machine needs to further:

Integrate with the Industry 4.0 architecture: Connect with the MES system to automatically distribute order-to-die-cutting parameters;

Expand material boundaries: Develop die-cutting solutions for metal foil and bio-based composite materials;

Build a modular design: Customers can freely choose printing and quality inspection units (such as adding a CCD kit).

The ultimate market choice is never the machine itself, but its ability to transform “materials” into “competitiveness.”

Behind the 1850mm width lies the scale of domestic manufacturing’s transformation from scale to value.