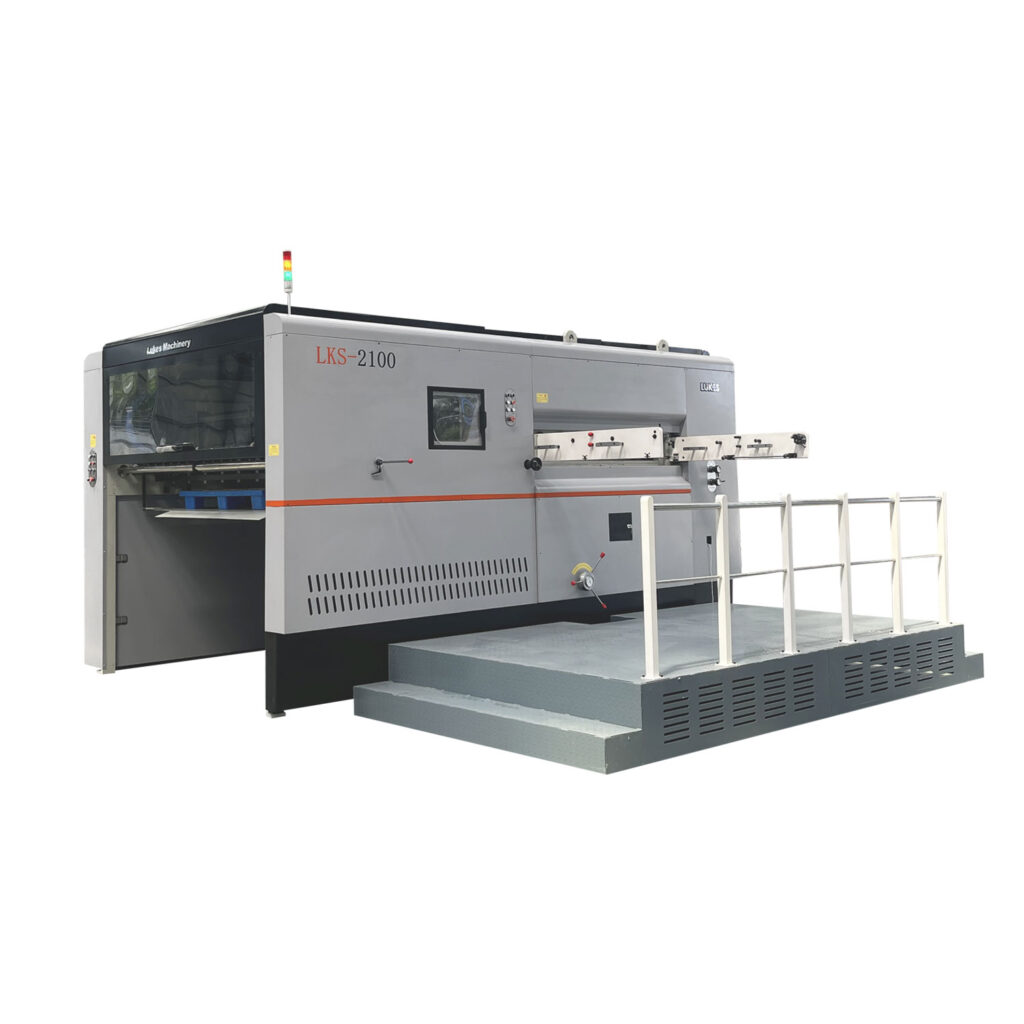

LKS1300(Q) Semi-Automatic Die Cutting Machine

Product Description

Semi-automatic die cutting machine is a new model developed by our company, which has the advantages of similar equipment at home and abroad.

Application:

Semi-automatic die cutting machine is mainly used in the production of cosmetic boxes, express packaging boxes, cigarette boxes, fruit gifts, food packaging, etc.

Model:

There are 4 sizes of this machine for you to choose from: 1300(Q), 1450(Q), 1620(Q), 1850(Q).

The paper edge waste removal function can be equipped according to customer requirements.

Advantage:

This machine has fine structure design and advanced program control.

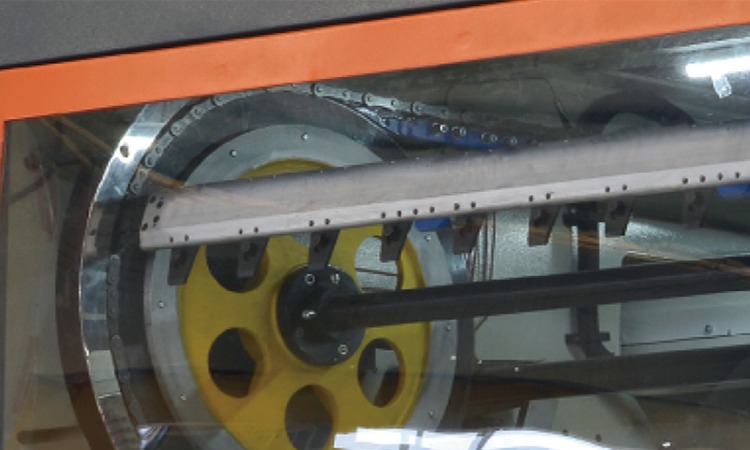

The high-quality crankshaft linkage mechanism is used to complete the main die-cutting movement.

The key components and main movements have passed stress analysis, computer simulation and other tests.

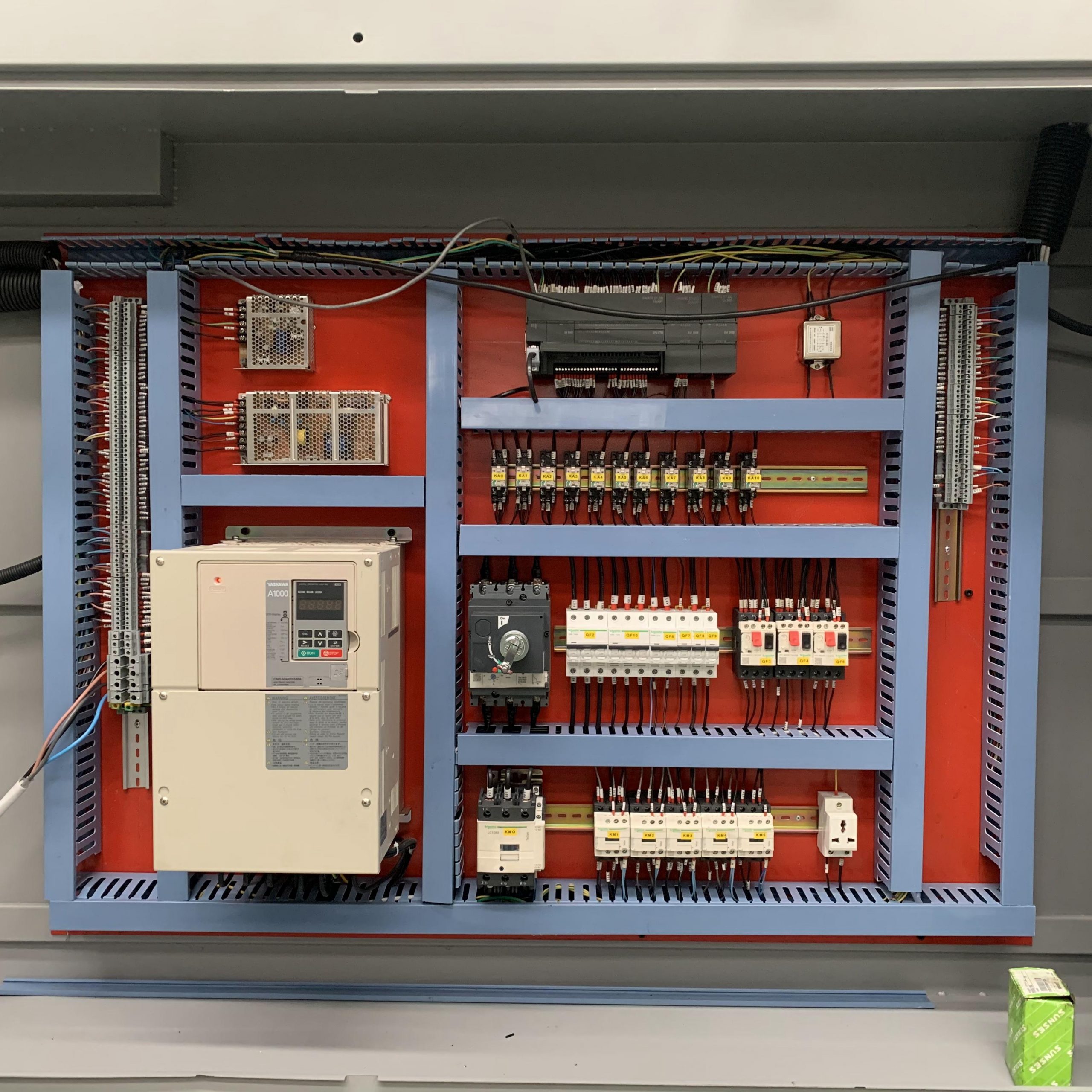

Using a full set of Siemens PLC programming and frequency converter linkage to achieve high control accuracy and stable operation.

The machine is equipped with 10-speed speed regulation, the maximum speed can reach 4500s/h.

Using high quality materials and precise design, the machine can work smoothly for a long time.

Long lasting.

Multi-national language presets make the operation more convenient.

Product design concept:

Reduce production costs and meet mass production needs.

Use a simple and convenient operating system to reduce the skill level requirements of operators.

Reduce labor intensity and improve work efficiency.

Serve:

LKS series semi-automatic die cutting machine is at the leading level in the country, with high cost performance and wide applicability. We focus on the needs of users and continuously upgrade and improve the structure and performance.

Lukes Machinery has been established for nearly 20 years. We have professional technicians and after-sales service team. Customers are located in dozens of countries around the world and are well recognized by customers.