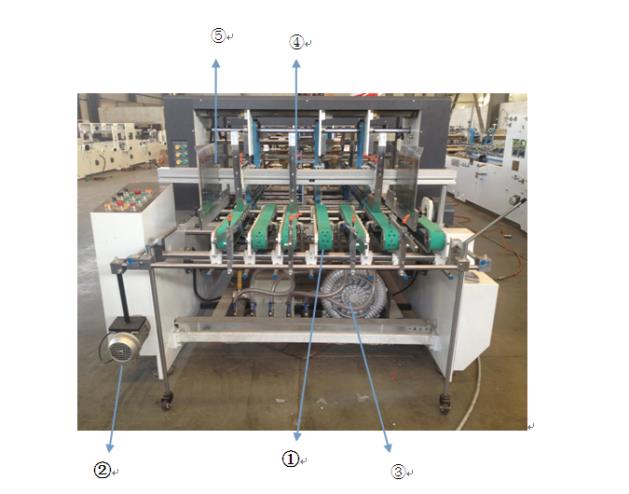

conveying and pressing unit

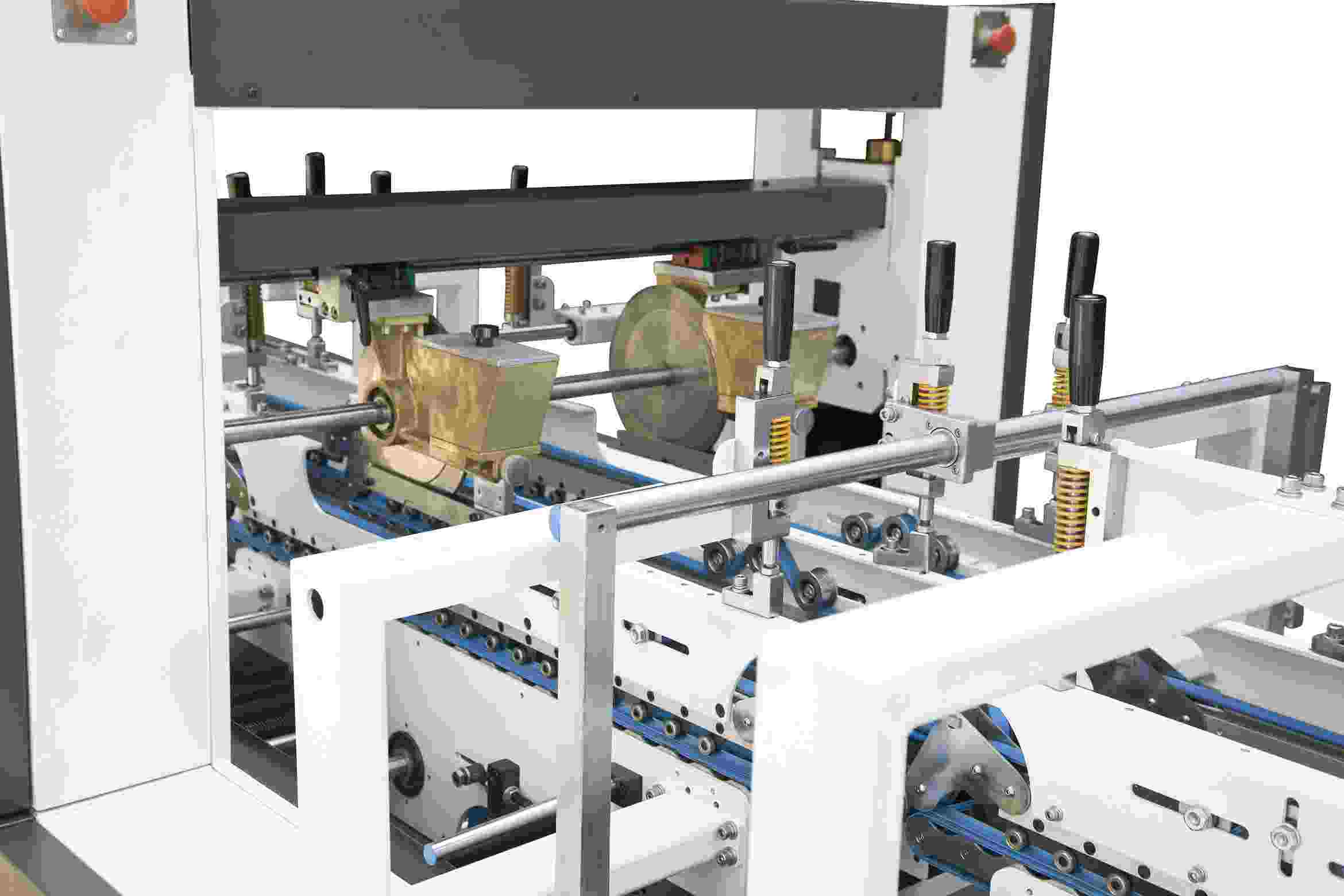

- There is a flapping device between the pre-pressing part and conveying and pressing part ( Option device for 1050 model and standard device for 1450 model). This device can do second correction to eliminate the fish tail phenomena.

- A counter-kicker is equipped with this part to mark the number of the pile to facilitate the operator’s pile number counting at the delivery part. The number to be kicked is set in the man-machine interface.

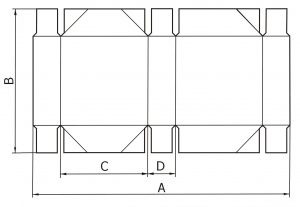

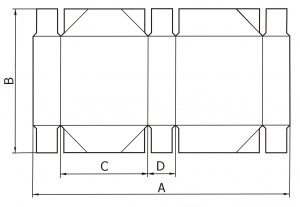

The conveying and pressing belt adopts driving transmission and pneumatic pressing mode. The pressure can be adjusted according to the needs or thickness of the box through pressure regulator. There are sponge stripe on the upper conveying belt to make extra pressure to the gluing part to make the gluing stronger.