LKS1080T Automatic Hot Foil Stamping Machine

Product Description

Model: LKS1080T Automatic Hot Foil Stamping Machine

Application:

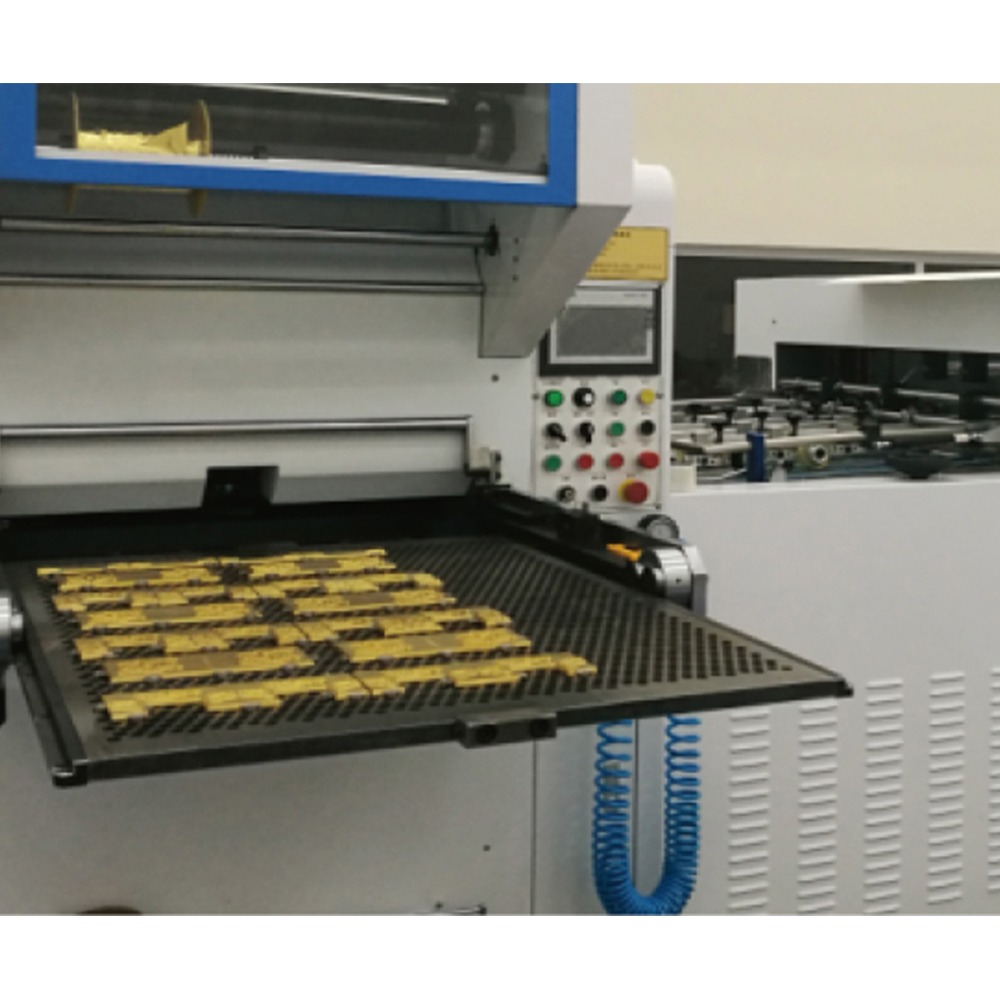

Automatic hot foil stamping machine is mainly used for die cutting of cartons, cartons, trademarks, Foil Stamping, creasing and cold embossing in the packaging and decoration industry.

Especially all kinds of advanced and fine prints, such as cigarette boxes, wine boxes, gift boxes, small home appliance boxes, cosmetic boxes, etc. can be used for ordinary and holographic anti-counterfeiting Foil Stamping on LKS800T automatic hot foil stamping machine, as well as bump indentation, In order to obtain three dimensional, exquisite and beautiful printed products.

Features:

LKS1080T Automatic Hot Foil Stamping Machine realizes automation from paper feeding, die cutting, hot stamping, and paper delivery. Dynamic detection, fault display, non-stop sampling and other functions. It also has the advantages of high die-cutting pressure and high registration accuracy.

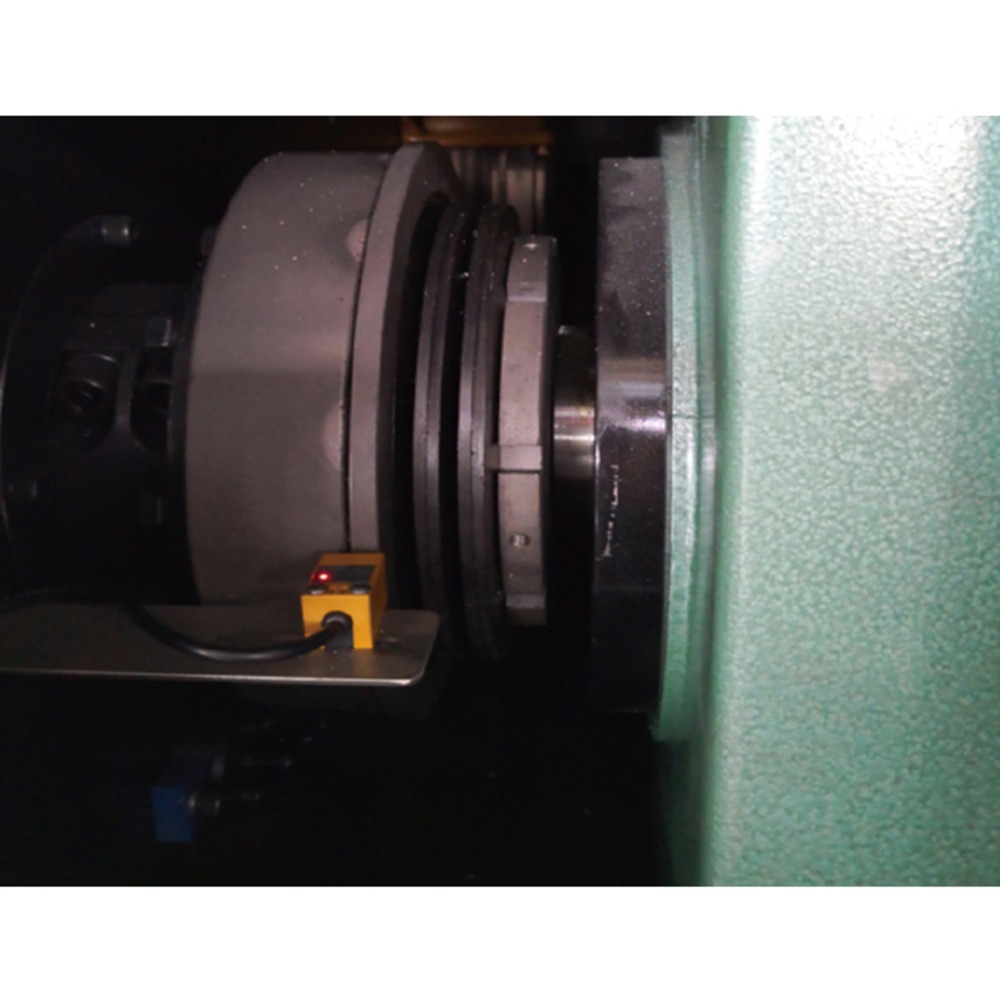

The main drive system of the machine is equipped with a pneumatic clutch and a braking device; the main sprocket shaft is equipped with a torque limiter (safety clutch); and multiple safety detection electric eyes and safety devices, etc.; Injury and equipment damage caused by the user, and fully protect the safety of personnel and equipment.

Lukes Machinery is one of the leading supplier manufacturers of automatic hot foil stamping machine in China, our factory high qualityautomatic hot foil stamping machine at competitive price for sale.