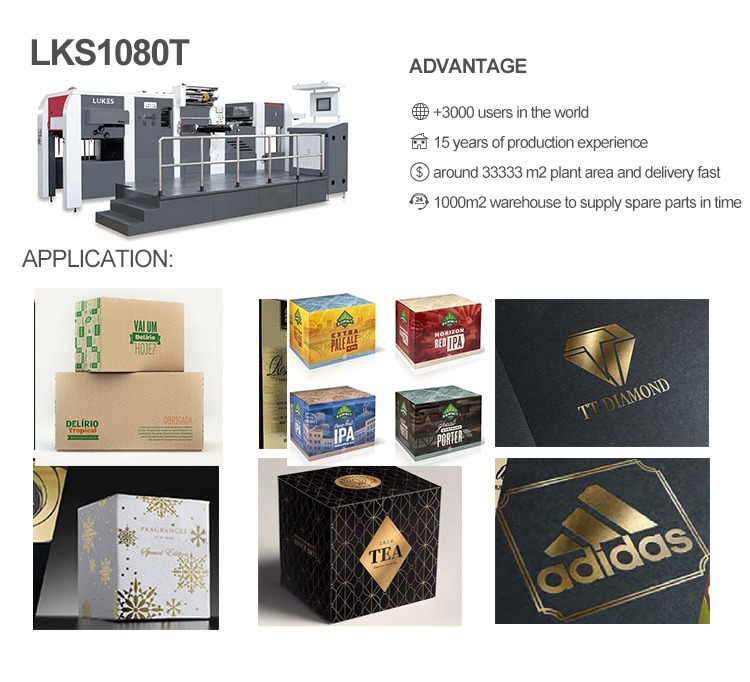

LKS1080T Automatic Foil Stamping Machine

Product Description

Model: LKS1080T Automatic Foil Stamping Machine

Model introduction:

●Automatic Foil Stamping Machine is mainly used for die cutting and creasing, bronzing and hot and cold embossing of cartons, cartons or trademarks in the packaging and decoration industry.

●Automatic Foil Stamping Machine adopts computer control and is a high-tech product of mechatronics. It applies multimedia technology, gate array, AC servo system and other high tech technologies to realize paper feeding, die cutting, bronzing, boosting and buckling. , Foil collection, paper delivery, skipping, counting, heating, preset heating, fault display, and automation of the whole process of detection.

●Automatic Foil Stamping Machine is easy to operate, safe and reliable, fast speed, high pressure, high precision, good quality and other advantages to win the trust of users.