1620B Automatic Die Cutter Machine With Stripping

Product Description

Model: 1620B Automatic Die Cutter Machine

Description:

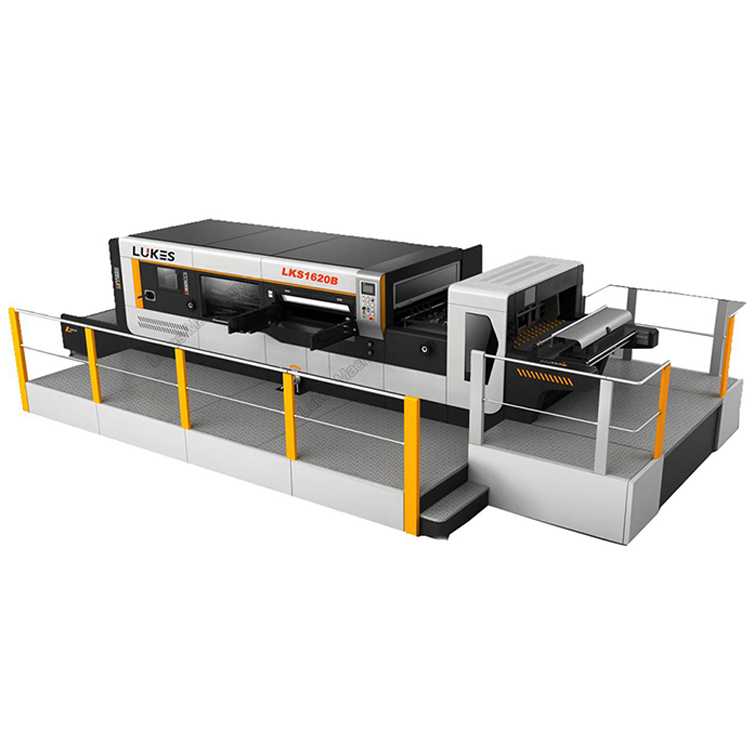

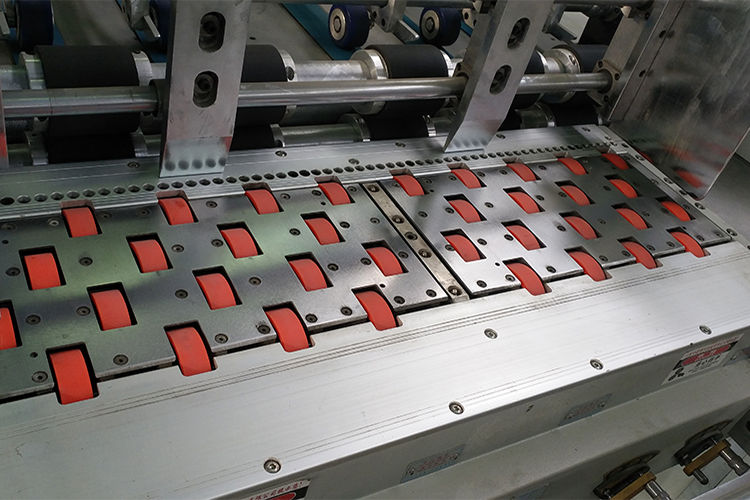

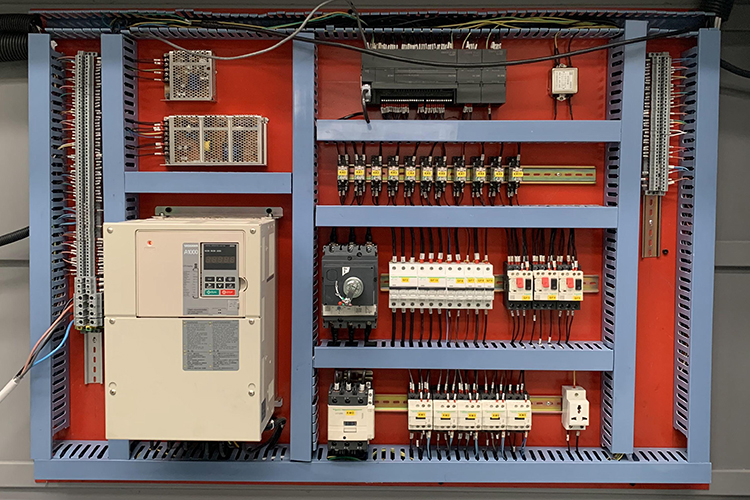

The 1620B Automatic Die Cutter Machine adopts a unique servo type leading edge feeding method, which can adjust the length of the paper transfer arbitrarily, and minimize the damage to the strength of the corrugated paper. Conveying, the air volume is steplessly regulated by the frequency converter;

The leading edge paper feeding high pressure fan controls the air volume by frequency conversion, which is suitable for most paper. The surface paper and bottom paper that are wrongly mounted will never be damaged, and can be reused to reduce waste.

The wallboard of the whole machine is made of 80mm thick steel plate, and the platform is all made of high strength ductile iron;

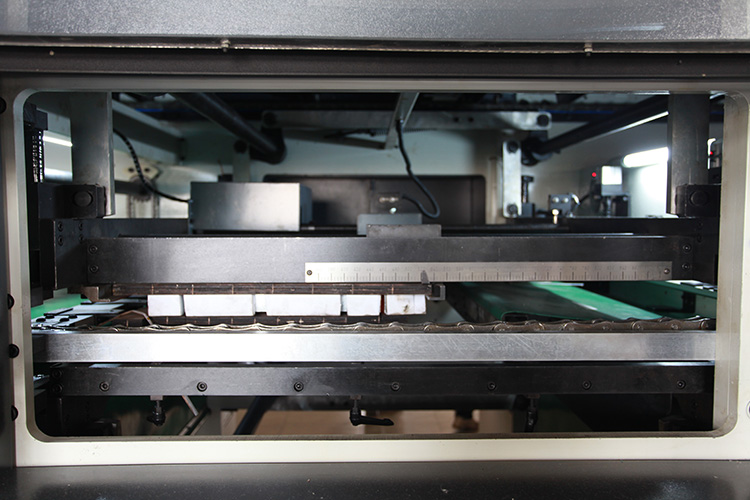

Automatic Die Cutter Machine adopts Taiwan Shengbao intermittently to ensure high precision and long life;

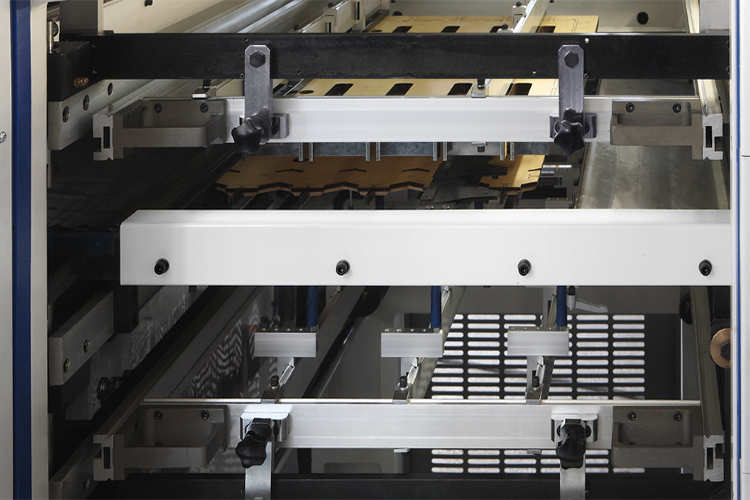

The stripping part adopts the international central positioning locking plate device, which is easy to change the plate, and the stripping design is all-in-one.

Automatic Die Cutter Machine is equipped with a lifting platform to facilitate paper loading without stopping, and automatic counting without stopping paper output design;

Imported PLC control, touch screen adjustment, all adjustments are adjusted by motor. Save time and effort, die cutting precision is controlled by fiber optic switch, automatic stop for loose board and fault, and the cause of the problem is reflected on the touch screen.

Introduction:

Lukes Machinery is one of the leading supplier manufacturers of Automatic Die Cutter Machine in China, our factory high quality 1620B Automatic Die Cutter Machine at competitive price for sale.