LKS-1050H(Q) High Speed Auto Feed Die Cutting Machine

Product Description

Model: 1050H(Q) Auto Feed Die Cutting Machine

Application:

High speed auto feed die cutting machine it is suitable for producing high-quality light and thin paper boxes.

Suitable for die cutting and creasing toy boxes, cigarette boxes, wine boxes, packaging boxes, etc.

This paragraph can freely choose the waste removal function.

Advantages:

1. The die cutting speed is fast, up to 7500 sheets per hour.

2. High precision of die cutting.

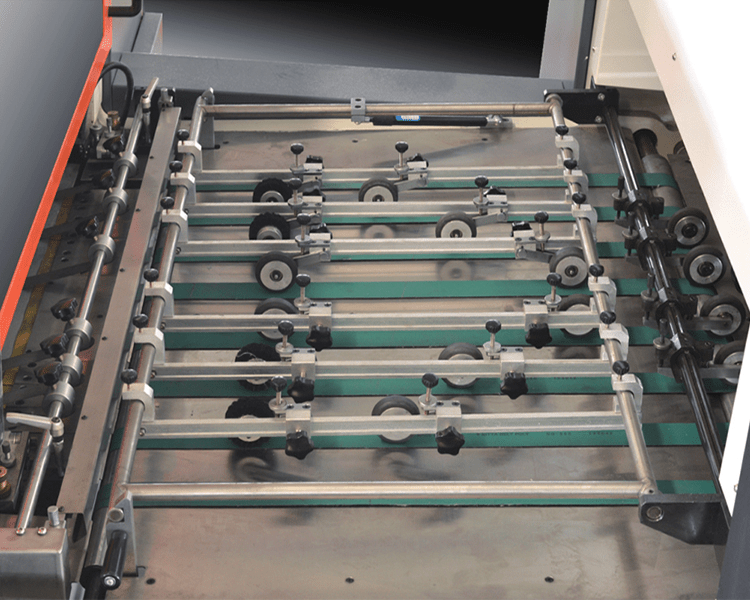

3. Pre loading mechanism, equipped with automatic fine-tuning function of paper table and non stop cycle paper loading function (optional). It can save paper change time and improve work efficiency.

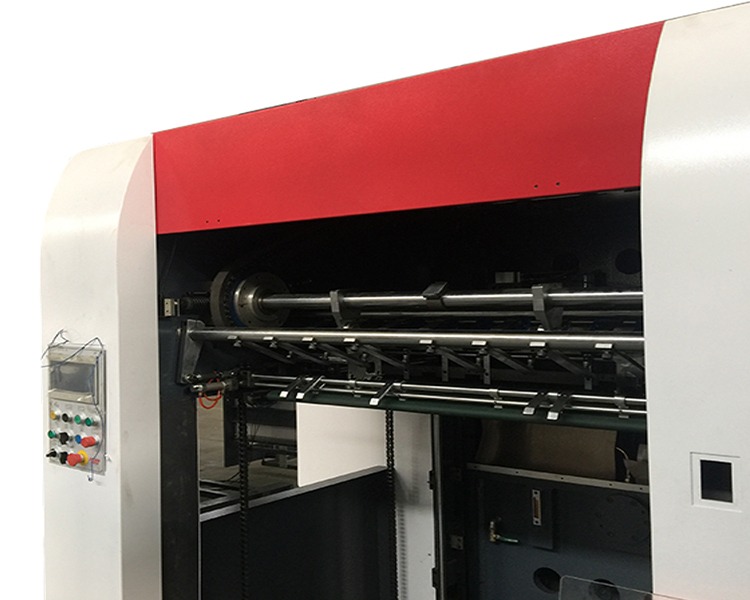

4. The feeding bridge is driven by an independent servo motor, which can realize continuous overlapping feeding and single feeding.

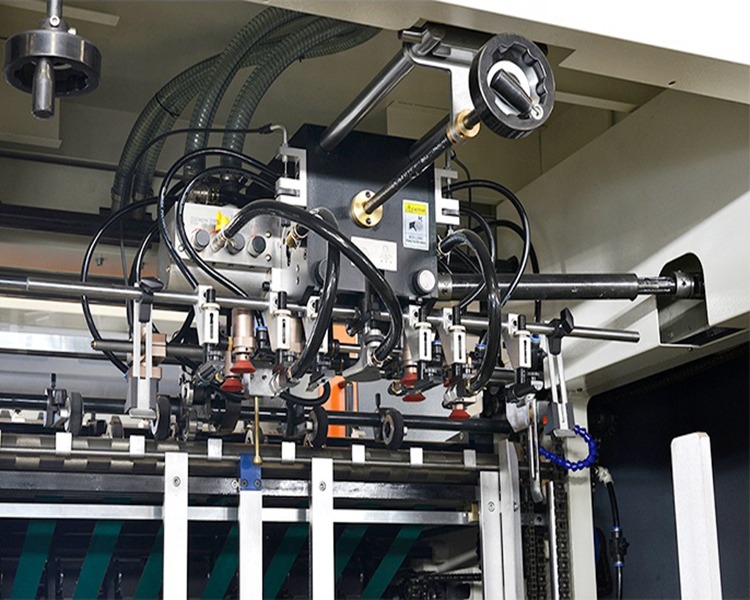

5. Front stop gauge and side pull adjustment position, pull gauge/push gauge can be used alternately to adapt to different thicknesses of paper. There is no indentation, flattening and other phenomena when feeding paper, which can improve the product quality. On click conversion, easy to use.

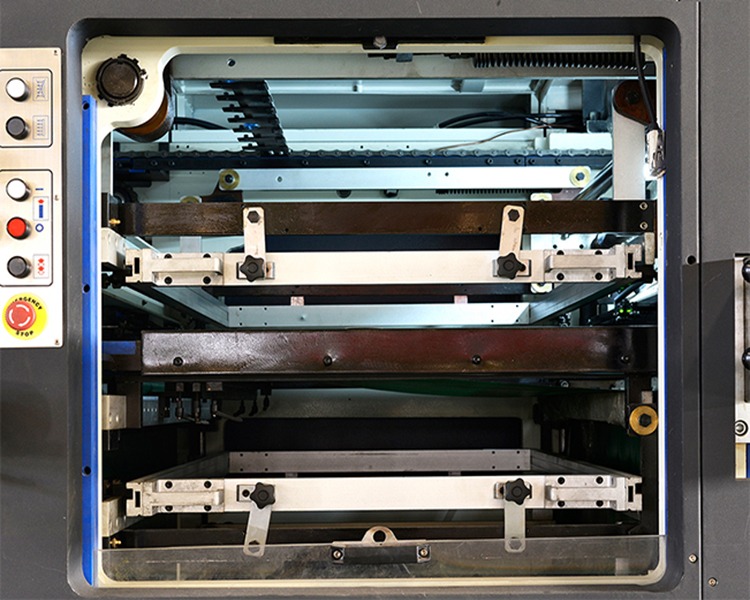

6. This machine uses high precision parts as a whole. The core components are manually polished, with high precision, good lubrication effect and high pressure, which can meet the die cutting of dense grid patterns.