Product Description

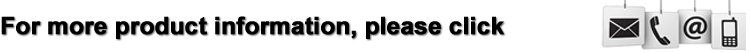

1650G Automatic Die-Cutting Machine Advantage:

1. Automatic die-cutting machine which adopts high technology with gear main drive can run max speed 5500s/h, shorter preparation process and perfect quality, which professional applies to all kinds of corrugated board.

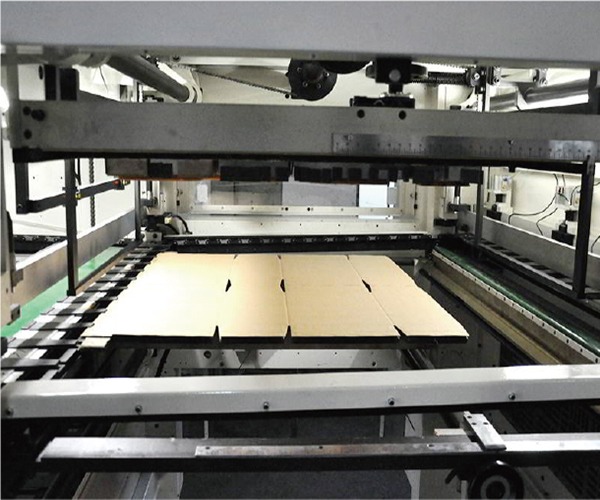

2. Paper hold down pressing plate is adjustable to adapt warped board, no double sheets to ensure continuous and smooth feeding.

3. Front gauge non-stop back and forth adjustable to accommodate variation in gripper margin.

4. Main drive adopts high quality precision worm gear and toggle system.

5. Centreline system for quick stripping tool set up and change over, compatiable with centreline Il.

6. Front edge waste removal system removes and transfers waste edge outside the machine visa conveyor belt

7. Counter can set based on your products stack request, which will be improve working efficiency.

8. Motorized upper frame suspending hoister.