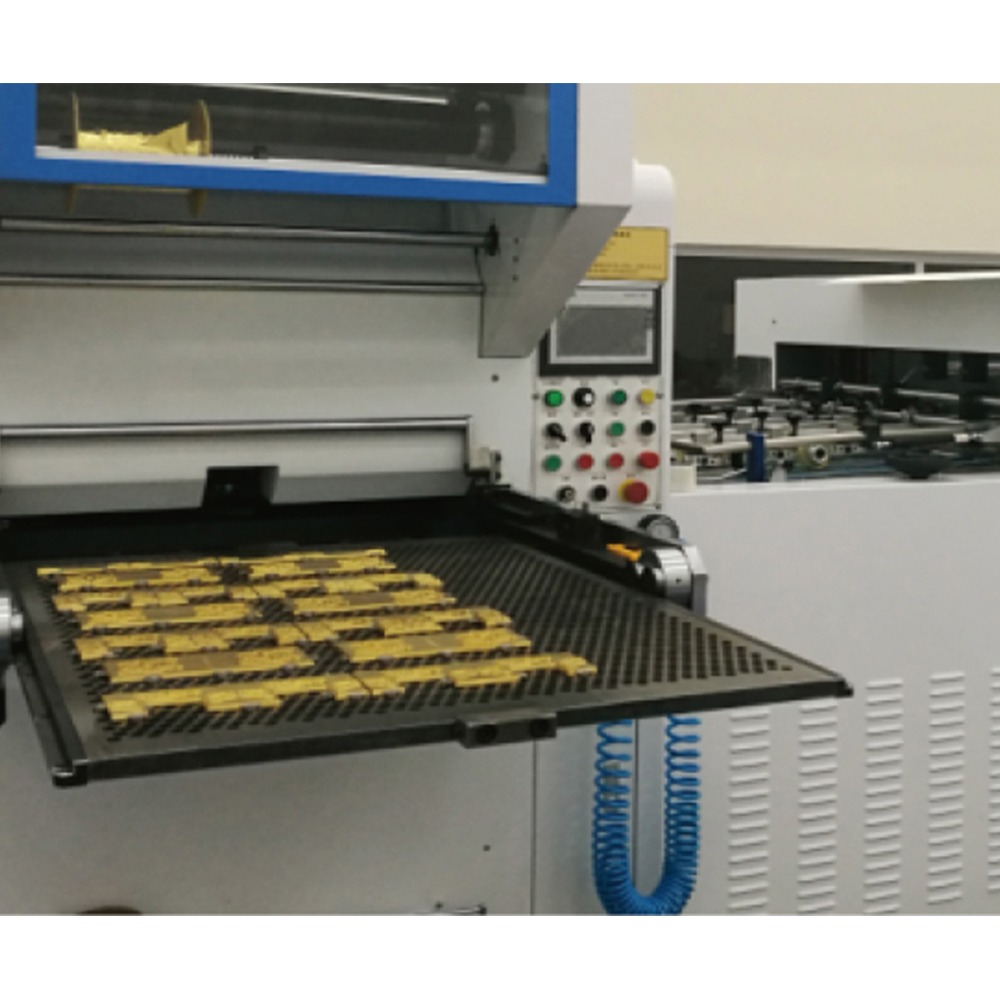

LKS1060T Full Automatic Hot Foil Stamping Machine

Product Description

LKS1060T full automatic hot stamping machine is high end models, aggravating machine, bronzing, deep embossing, die cutting , characterized by pressure, large parts size , the machine iteself , the weight of body long life.

The main chain of imports the main drive bearing , PLC, inverter and various electrical switches sophisticated performance, accuracy long life.

Redesigned large torquelimiter to ensure that the machine is running safer.