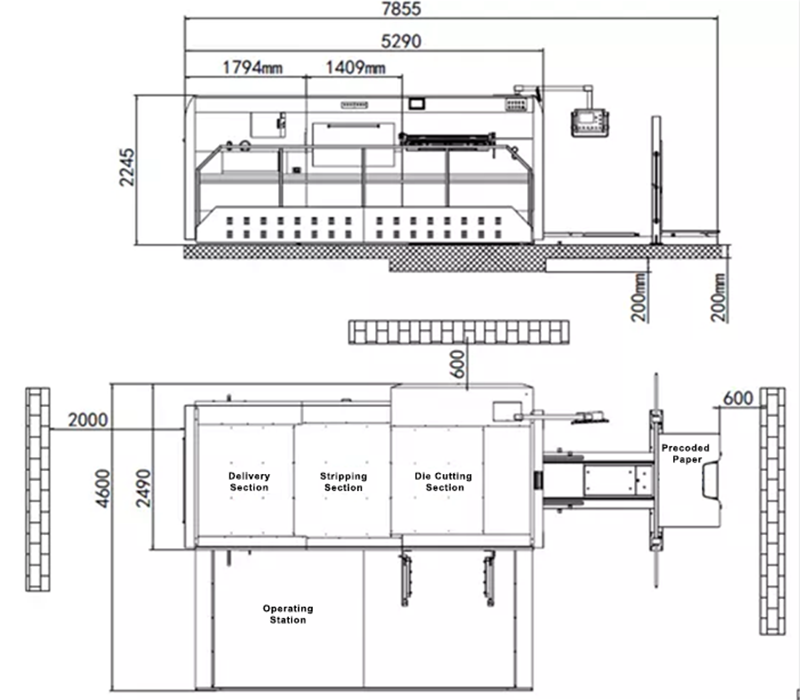

LKS1160ED(Q) Semi Automatic Die Cutting Machine with Feed Table

Product Description

LKS-1160ED(Q) Semi Automatic Die Cutting Machine with Feed Table:

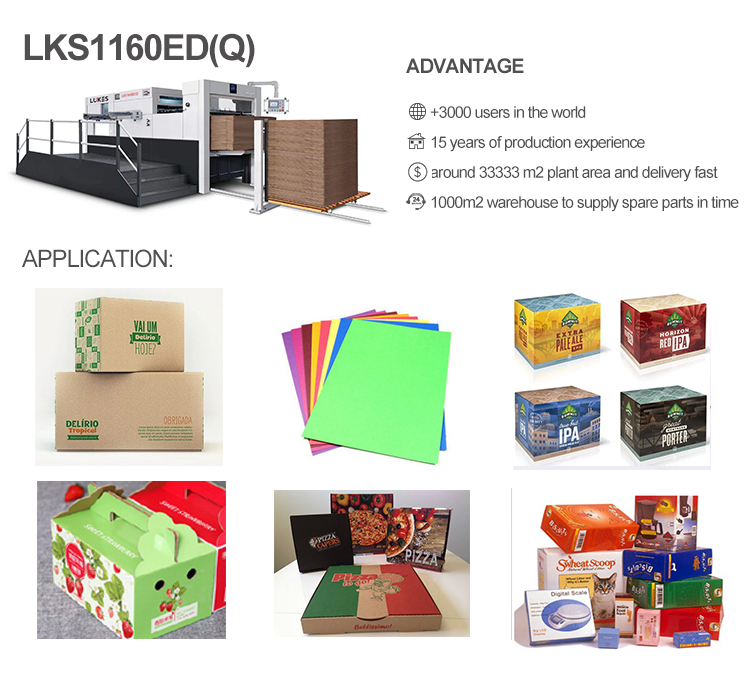

This model is very suit for offset carton package which has cardboard/mono carton/duplex board and also corrugated board. (one machine can do all of your board)

Colorful offset printing carton has high request for cut precision.

Semi automatic die cutting machine with feed table can adjust the feed precision to ensure arrived correct gripper bar. sometimes, if operator feed the sheet slop, the side lay can automatic adjustment.

Semi Automatic Die Cutting Machine with Feed Table Features:

1. Adopt nodular cast iron-QT500-7, the mainframe wallboard casting by special technology process, thus featuring by high

strength, never deformation and ensure the safety of the mainframe wallboard.

2. Adopt Taiwan-imported intermittent mechanism to ensure that the machine operates accurately and reduce the occurrence of

failure rate.

3. The whole machine all uses SKF\NSK imported original bearing.

4. The whole machine uses original parts imported from France Schneider,Japanese OMRON.

5. Key parts of gripper bars are imported from Japan.

6. The craft shaft is adopts Germany Ni-Cr-Mo metal steel, with high precision and will never deforms.

7. Use the centerline positioning system to realize fast plate changing of worksheet.

8. Equiped with Dayuan first-developed pressure servo control device, ensure fast and smooth adjusting of die cutting pressure.

9. Equip with touch-screen operation interface in both Chinese and English.

10. All adopt Taiwan AIRTAC pneumatic components to ensure every pneumatic action performs accurately.

11. Main motor from Siemens,ensure stable operation.