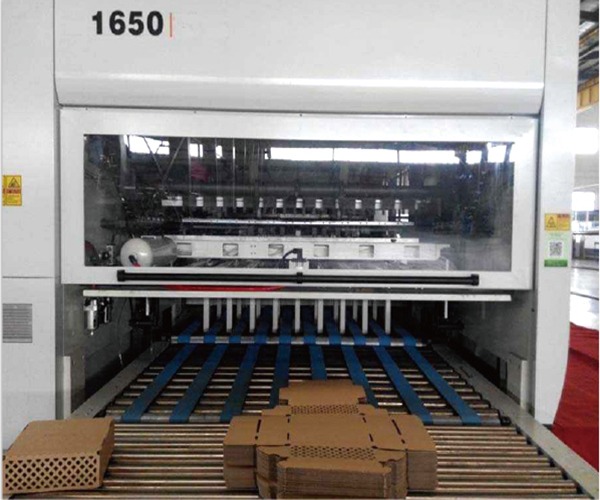

1650G high speed automatic die cutting machine for corrugated carton

Product Description

Model: LKS1650G High Speed Automatic Corrugated Die Cutting Machine

Introduction:

Lukes Machinery is one of the professional corrugated die cutting machine manufacturers and suppliers in China.

Description:

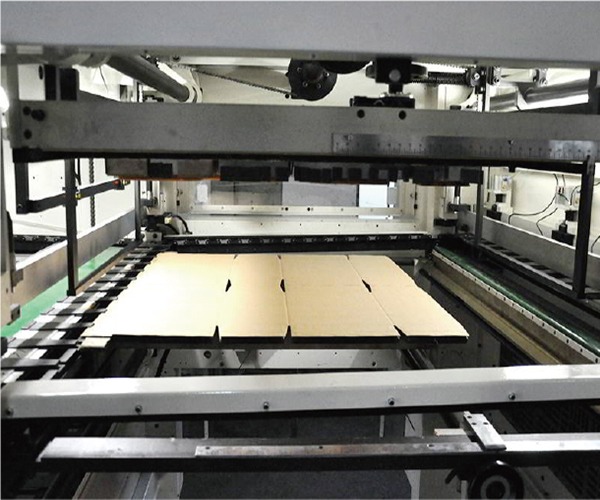

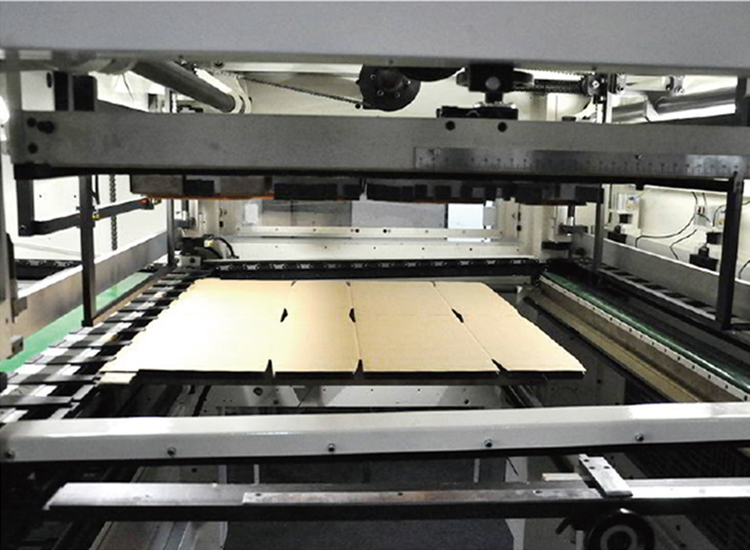

Corrugated die cutting machine automates the process from feeding, die-cutting, to delivery.

Features:

Corrugated die cutting machine uses “human-machine interface” to display the working speed of the machine, the number of sheets processed, the total running time and working status of the machine;

Realize the dynamic monitoring of the input points, output points and various faults of the programmable controller, which makes troubleshooting and operation more convenient.

(Optional) The preset technician function can realize the stop of the air pump according to the preset number, and automatically mark it;

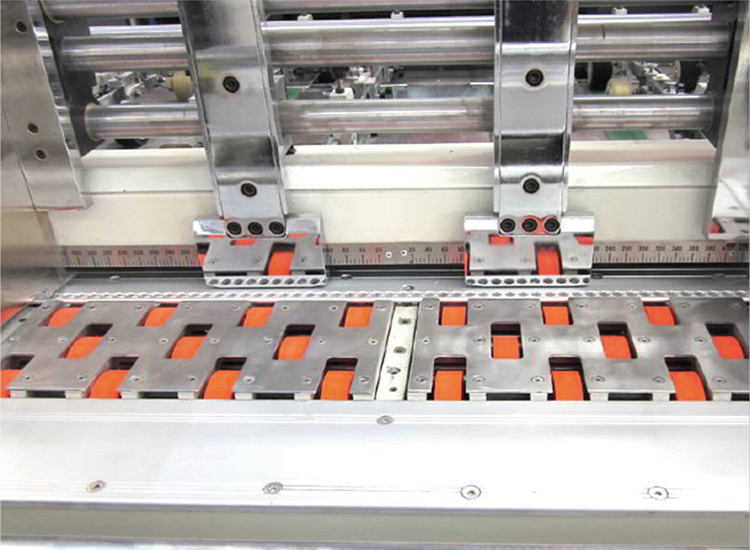

The electronic cam composed of the encoder and the programmable controller is accurate, reliable, and easy to adjust.

The frequency converter is used to control the main motor, stepless speed regulation, stable operation, low noise, and energy saving. , And the die-cutting pressure is high, the registration accuracy is high, and there are many sensors and safety protection devices to ensure the normal operation of the machine and the safety of personnel.

The main drive system of the Corrugated die cutting machine is equipped with a pneumatic clutch, and a torque limiter (safety clutch) is installed on the main sprocket shaft to avoid injury and damage to operators, operators and equipment due to emergencies, so as to ensure personal safety and safety. Device safety.

Corrugated die cutting machine is equipped with many safety protection devices in the whole machine. Once the person touches or enters the area, its alarm device will automatically alarm and the equipment is in shutdown state.