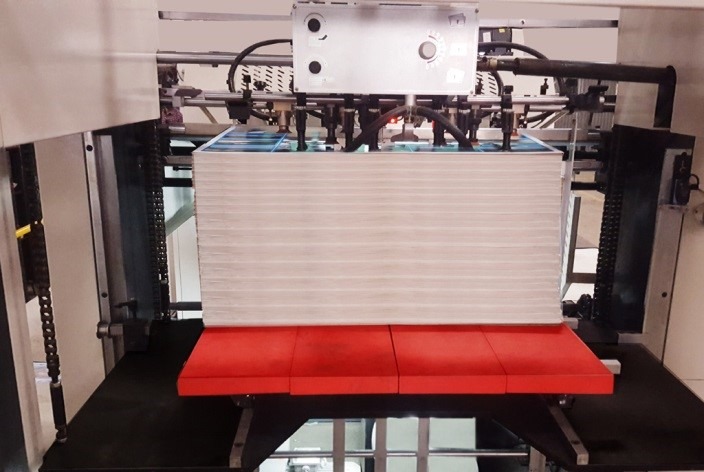

1050 Fast Speed Spot UV Coating Machine

Product Description

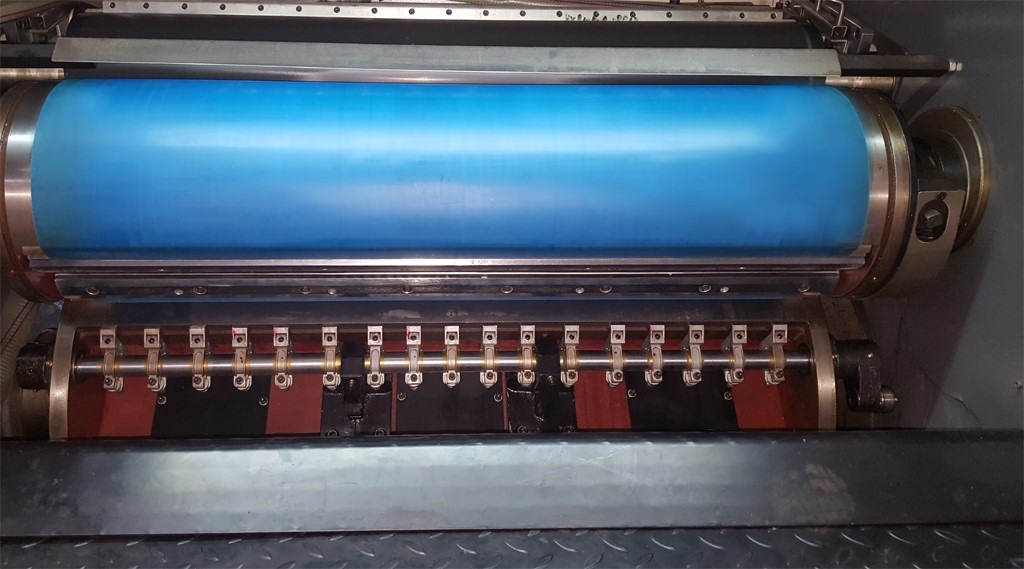

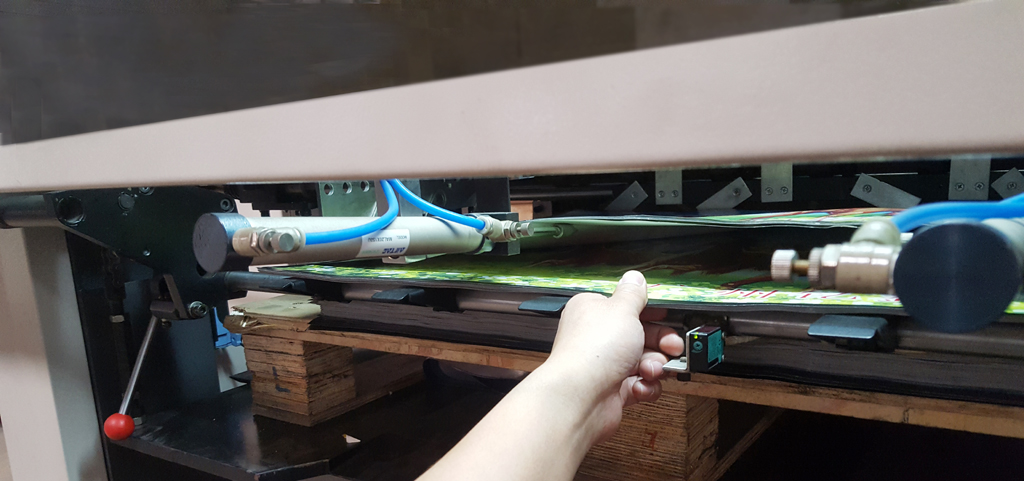

1050 fast speed spot uv coating machine is a water / oil dual-use high-speed local / full UV polishing equipment for blankets or flexible version of the plate for the local or full glazing, partial polishing overprint accurate, uniform and not squeeze the oil. Suitable for books and periodicals, advertising, color box, film, high-end packaging and other printed text and pattern of local overprint or full glazing, improve the quality of printed materials, increase beauty. Multi-security design, security and user-friendly operating procedures to ensure that the operator’s personal safety and ease. Developed by the company’s high-speed local UV polishing machine, the application of the whole pendulum-type Diao-style paper delivery, to 10,000 per hour speed of high-speed paper.

For more information consultation: [email protected]